Professional & Experienced Manufacturer of Soft & Hard Shell Jackets

Your Reliable & Trusted Manufacturer of Soft & Hard Shell Jackets

We Manufacture Custom Soft & Hard Shell Jackets

Premium Quality & Competitive Price & On-time Delivery

We Offer You One-stop Solutions by

Our Rich Experience & High-level Professionalism

Start Your Own Journey of Soft & Hard Shell Jacket

Find the perfect solutions of fabric & manufacturing for your own shell jackets by exploring our service & manufacturing with rich experience & high-level professionalism

A soft shell jacket is crafted using lightweight, stretchable fabrics like polyester or nylon blends, often with a Durable Water Repellent (DWR) coating. It provides comfort, mobility, and moderate weather protection.

The focus is on combining breathability and flexibility, with features like bonded layers or fleece linings for added warmth.

Precision stitching and ergonomic designs enhance mobility, making them ideal for active use.

The Manufacturing of

Soft Shell Jacket

&

Hard Shell Jacket

Soft shell and hard shell jackets are two essential types of outdoor apparel, but they serve different purposes, thus require different manufacuring.

The manufacturing of soft and hard shell jackets involves advanced processes to ensure performance, durability, and comfort.

Both types demand specialized equipment and expertise to meet outdoor performance standards.

A hard soft jacket requires a more technical approach. It uses laminated fabrics with waterproof membranes.

The manufacturing involves sealing seams, layering materials for strength, and ensuring maximum weatherproofing without compromising breathability.

Attention to detail in weather-resistant zippers, cuffs, and hoods is critical for creating reliable protection in extreme conditions.

Let's Work Together To Create Your Custom Soft & Hard Shell Jacket

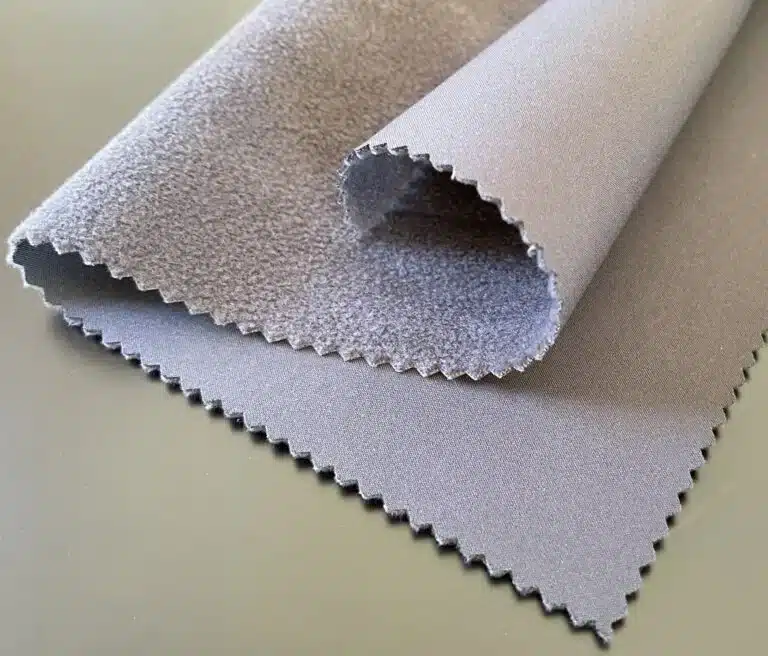

Soft Shell Fabric

Soft shell fabric is designed for flexibility, comfort, and moderate weather protection. Its regular specifications typically include:

-

Material Composition:

- A blend of polyester and spandex or elastane for stretch and durability.

- Nylon can also be used for added strength and abrasion resistance.

- Most common: 94% Polyester, 6% Spandex

-

Weight:

- Usually ranges from 180gsm to 340gsm (grams per square meter), depending on the level of warmth and protection required.

-

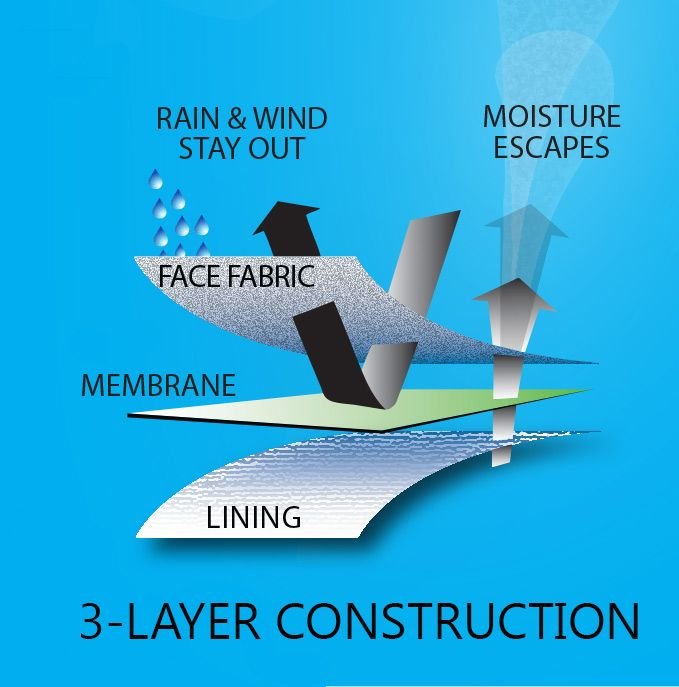

Layers:

- Typically features 2-layer or 3-layer construction:

- Outer Layer: Durable, water-resistant (DWR-coated) fabric.

- Middle Layer: Optional breathable membrane for wind resistance and waterproof.

- Inner Layer: Brushed fleece or soft knit for comfort and insulation.

- Typically features 2-layer or 3-layer construction:

-

- Treated with a DWR coating, ranging from 800-20,000 mm.

-

- High breathability for moisture-wicking during active use, often rated as 800-20,000 g/m²/24h.

Hard Shell Fabric

Hard shell jackets are made from highly durable, weatherproof fabrics designed to protect against extreme outdoor conditions. These jackets typically use membranes, which combine a waterproof, windproof, and breathable outer layer.

The fabric usually features a 3-layer or 2.5-layer construction, with the membrane sandwiched between a durable outer shell and a comfortable inner lining. The outer layer is often treated with a Durable Water Repellent (DWR) coating to repel water, while the membrane ensures breathability. This robust design makes hard shell jackets perfect for heavy rain, snow, and strong winds.

Heat-Taped Seams Sealing

Heat-taped Seams Sealing is a crucial process in shell jacket manufacturing that ensures maximum waterproof protection. During this process, a heat-activated tape is applied over the seams of the jacket, bonding the fabric layers without stitching.

This method eliminates needle holes that could allow water to penetrate, creating a completely waterproof barrier. It also enhances the jacket’s durability and maintains its lightweight profile. Heat-taped seams sealing is essential for producing shell jackets capable of withstanding heavy rain, snow, and harsh outdoor conditions while preserving breathability and flexibility.

Discover Our Commitment & Process to Quality Control

Discover our commitment to quality and rigorous quality control process for custom soft & hard shell jackets. Learn how we ensure high standard quality in every product.

Identity Logo Presented

Embroidery

Plain Silkscreen Print

Embossed Print