Custom Puffer & Down Jackets Manufacturer

Customization & Private Label Services

Your Reliable & Trusted Manufacturer of Puffer & Down Jackets

We Deliver Puffer & Down Jackets with Your Ideas & Identity

Premium Quality & Competitive Price & On-time Delivery

We Offer You One-stop Solutions by

Our Rich Experience & High-level Professionalism

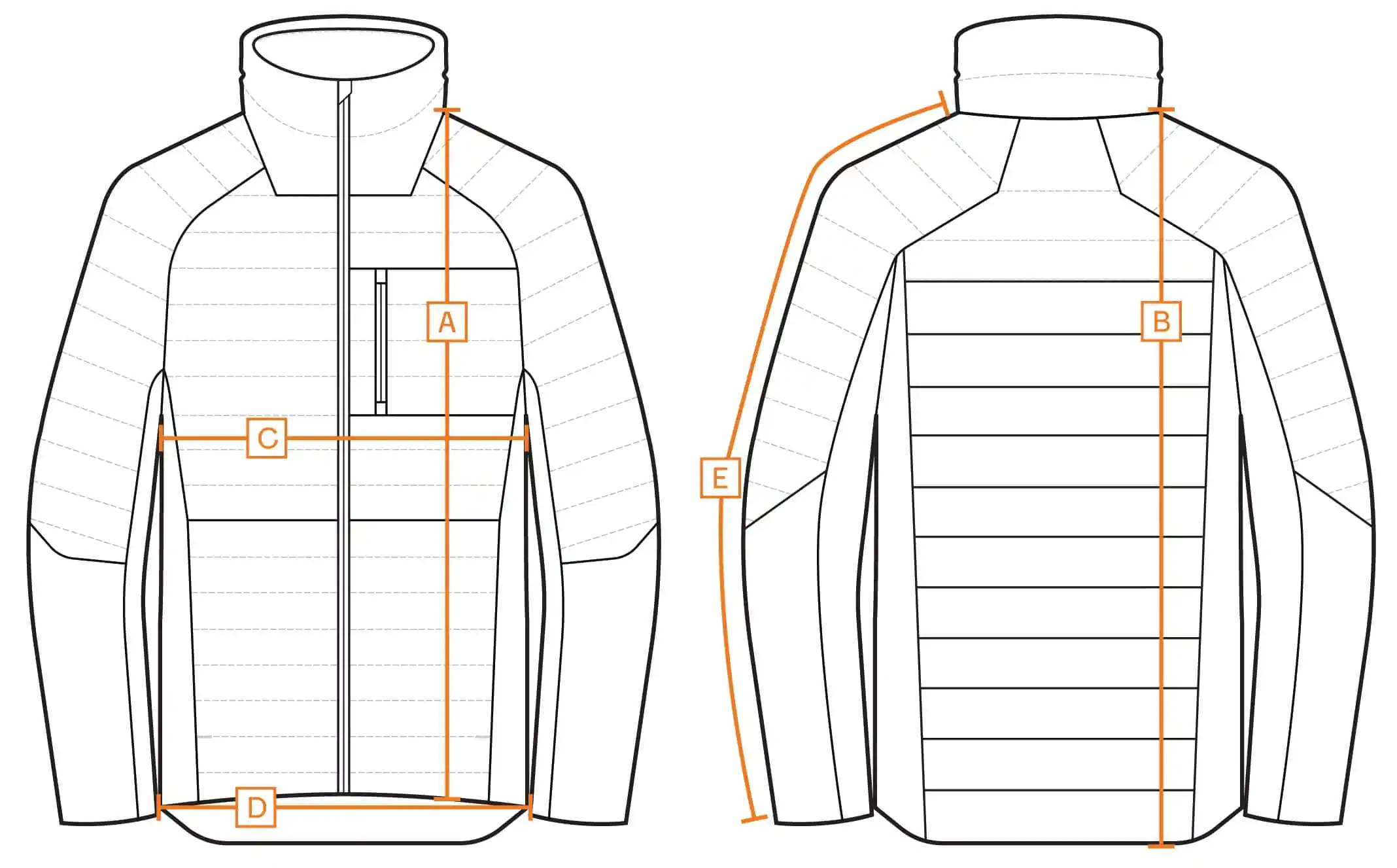

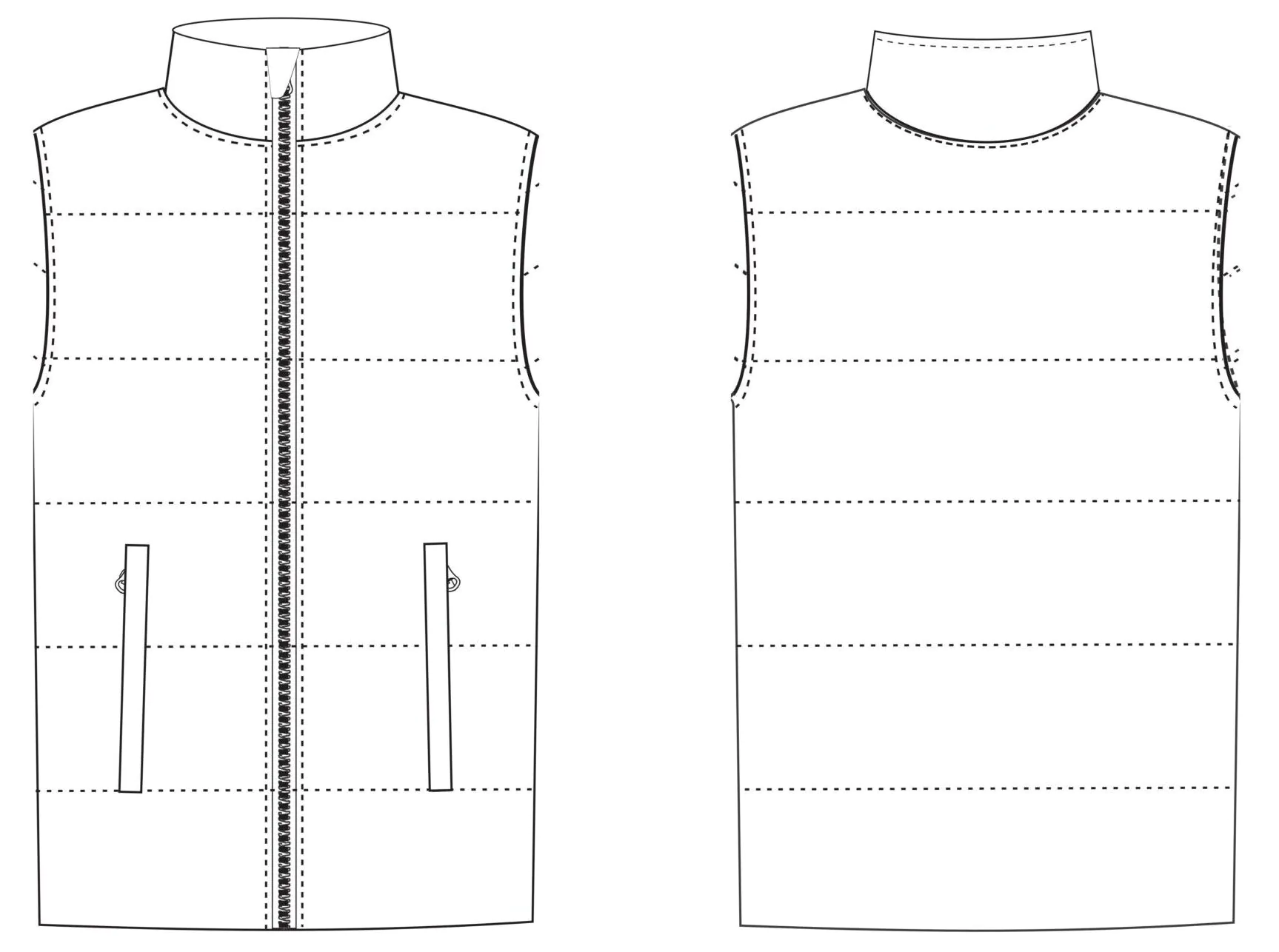

Classic Lightweight Water-repellent Puffer Jacket

Shell Fabric:

20D/380T 100% Polyester or Nylon

Tightly Woven, Light Weight, Durable, Shiny or Matt

Water-repellent, Windproof, Downproof

Filling Insulation:

100% Synthetic Polyester

Optional 3M Thinsulate®, PrimaLoft®, Zermory®

Natural Duck or Goose Down, 500-800+ Fill Power

Optional RDS(Responsible Down Standard) Certification

Customization Options:

Identity Color, Embroidery or Printing Logo, Private Label

Adjustable cuffs with elastic tape or hook-and-loop fasteners

Hood with drawstring, More pockets…

Your Custom Design

Size:

XS – 4XL, Standard or Custom Tailored Size Chart

Start Your Own Journey Of Puffer & Down Jacket

Find the perfect solutions of fabric & manufacturing for your own puffer & down jackets by exploring our service & manufacturing with rich experience & high-level professionalism

The Material & Manufacturing of Puffer & Down Jacket

Outer Shell Fabric

The outer fabric of puffer and down jackets is designed to provide durability, weather resistance, and style. Typically made from materials like nylon or polyester, it offers a lightweight yet robust layer that protects the insulation inside. Many outer fabrics are treated with a Durable Water Repellent (DWR) coating to resist light rain and snow.

For enhanced performance, some jackets feature ripstop weaves, which prevent tearing and increase durability in rugged conditions. These outer fabrics are carefully engineered to balance protection and breathability, making puffer and down jackets versatile for outdoor activities and everyday use.

Synthetic Polyester Insulation

Synthetic insulation in puffer and down jackets is a high-performance alternative to natural down. Made from polyester fibers, synthetic insulation mimics the structure of down clusters to trap heat effectively.

Its key advantage lies in its ability to keep warmth even when wet, making it ideal for wet or unpredictable weather. Synthetic insulation is also durable, hypoallergenic, low-irritant, low cost and easy to maintain.

Premium options like PrimaLoft® and Thinsulate® are soft, lightweight and compressible, ensuring comfort without adding bulk. This insulation is a go-to choice for outdoor enthusiasts seeking all-weather reliability.

Natural Duck & Goose Insulation

Natural down insulation is renowned for its exceptional warmth and lightweight properties, making it a premium choice for puffer and down jackets.

Sourced from the soft under-feathers of ducks or geese, down creates thousands of tiny air pockets that efficiently trap and retain body heat.

This insulation offers an outstanding warmth-to-weight ratio and excellent compressibility, allowing jackets to pack small and feel light. Ideal for cold and dry climates, natural down provides unmatched comfort and performance for outdoor and everyday use.

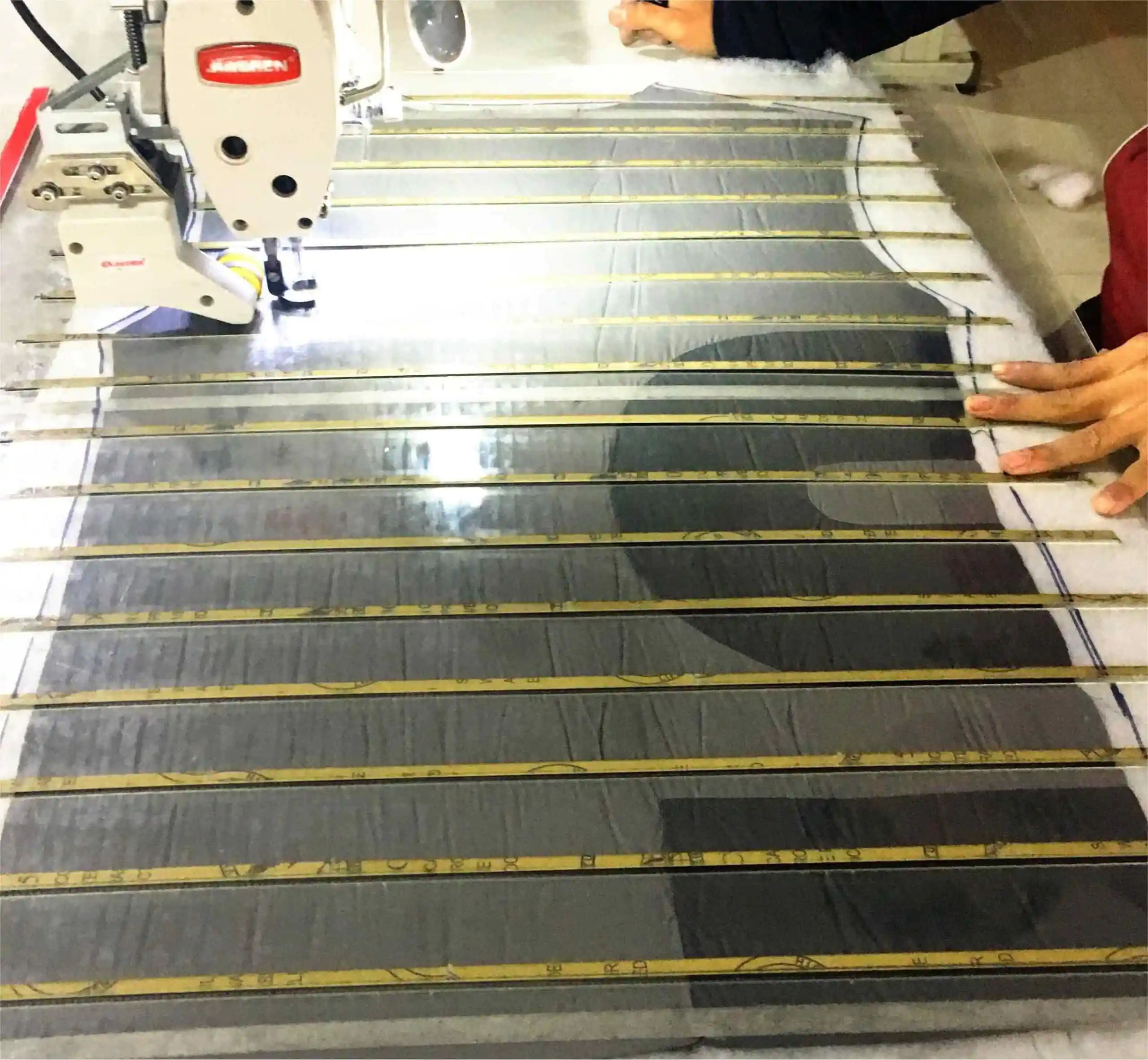

Template Sew

A template sew is a precise pattern or blueprint used in the manufacturing process to ensure accurate cutting, stitching, and assembly of the jacket.

It includes detailed outlines for each panel, as well as markings for seams, pockets, and insulation compartments. The template ensures consistency in sizing, fit, and design across multiple jackets, while also optimizing fabric usage to minimize waste.

Down Filling Machine

We use down filling machine in the production of high-quality down jackets. It automates the process of evenly distributing down insulation into the jacket’s compartments, ensuring consistent warmth and loft. The machine precisely measures and fills the down, minimizing waste and reducing human error.

This results in jackets that are lightweight, well-insulated, and comfortable. By using a down filling machine, we can improve efficiency and maintain quality control.

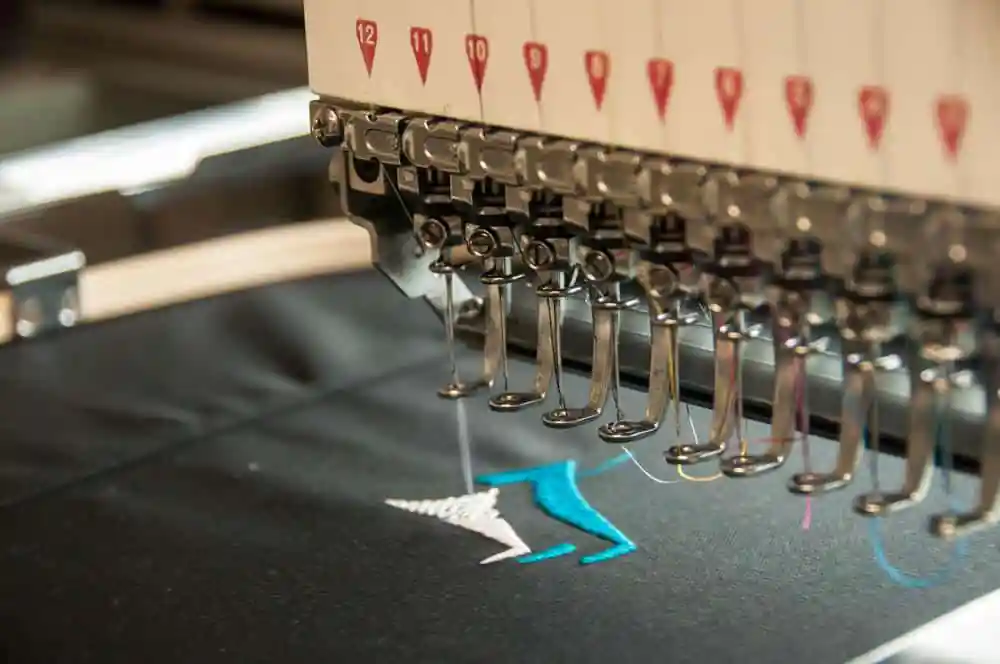

Identity Logo Solutions for Custom Puffer & Down Jacket

Embroidery

Screen Print

Embossed Print

Let's Work Together To Create Your Custom Puffer & Down Jacket

FAQ for the material and manufacturing of Puffer & Down jackets

Can you produce puffer and down jackets under OEM or private label?

What is the minimum order quantity (MOQ)?

MOQ depends on fabric type and color.

Polyester Insulation: usually 300 pcs per color.

Natural Down Insulation: usually 500 pcs per color.

100 pcs per color is workable with higher cost.

You can have multi sizes within this quantity.

Are puffer & down jackets fully waterproof?

No.

Puffer & down jackets are water-repellent, not fully waterproof.

DWR treatment is applied to the shell fabric.

What insulation materials are used in puffer jackets?

Puffer jackets are filled with synthetic fibers, such as polyester insulation.

Synthetic insulation performs better in wet conditions.

What insulation materials are used in down jackets?

Down jackets are filled with duck down or goose down.

Down clusters provide high warmth-to-weight ratio.

What is down-proof fabric?

Down-proof fabric is a tightly woven fabric that prevents down from escaping through the fabric.

How is down leakage controlled?

How is insulation fixed inside the jacket?

Insulation is held in place by quilting or baffle construction with our professional template sewing machines. This prevents insulation from shifting.

Can recycled and eco-friendly materials be used?

What does FP (Fill Power) mean?

Fill power measures the loft and quality of down.

Common fill power ranges from 500 to 800+ FP.

Can custom insulation weight and warmth level be developed?

Yes. Insulation weight (GSM or fill weight) can be customized to meet target warmth and market requirements.

Is RDS certified down available?

Yes.

Down can be sourced with RDS (Responsible Down Standard) certification upon request.

Can different down types be selected?

Yes.

Options include duck down or goose down, with different fill power levels.

Can size sets and pre-production samples be provided?

Yes. Size sets and PP samples can be produced before bulk production to confirm design, material, quality and fit.

Which jacket is lighter?

Down jackets are usually lighter and more compressible.

Which jacket is easier to care for?

Puffer jackets are easier to wash and maintain.

Down jackets require more careful care.

Which jacket is more affordable?

Puffer jackets are usually more cost-effective.

Down jackets have higher material cost.