Custom Soft & Hard Shell Jackets Manufacturer

15+ Years of Professionalism & Experience

OEM & Private Label Services

BSCI Audited Factory

Your Reliable & Trusted Manufacturer of Soft & Hard Shell Jackets

We Deliver Soft & Hard Shell Jackets with Your Ideas & Identity

We Bring Your Brand Vision to Life

Premium Quality & Competitive Price & On-time Delivery

We Offer You One-stop Solutions by

Our Rich Experience & High-level Professionalism

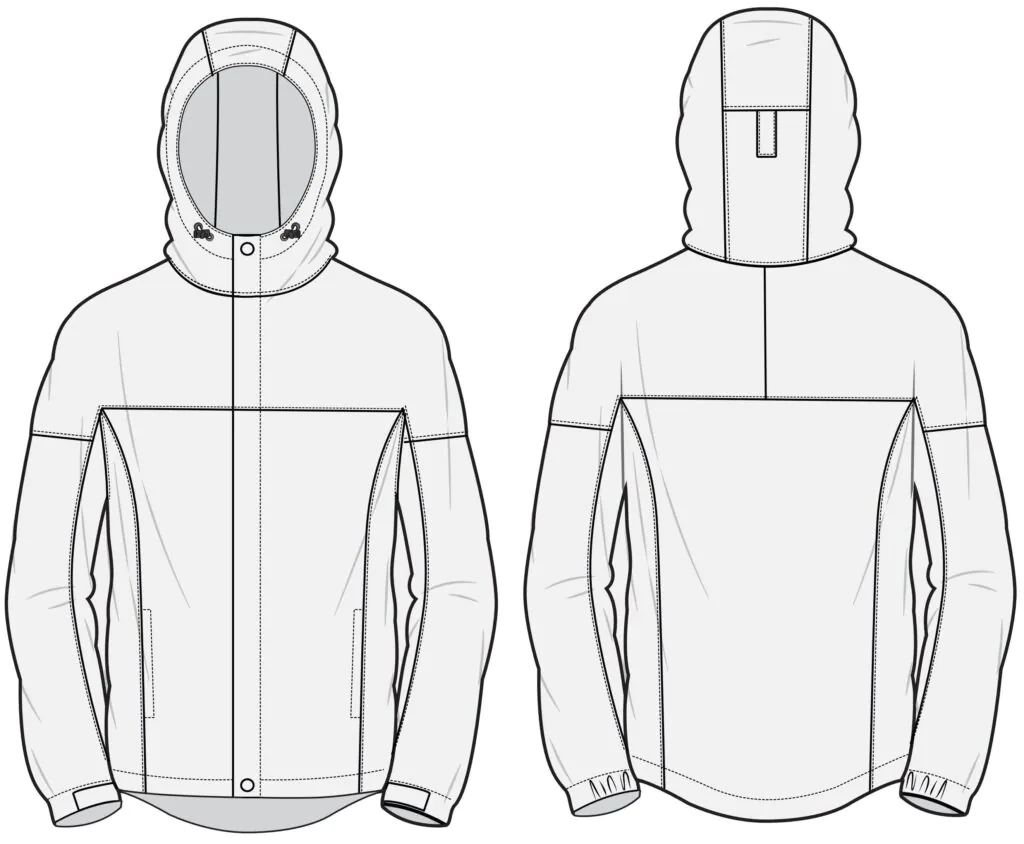

Classic Hooded Soft Shell Jacket

Fabric:

300-350 gsm, 94% Polyester 6% Spandex

Water-repellent Windproof Shell Fabric

Laminated with Waterproof Breathable Membrane

800 – 20,000 mm Waterproofness

800 – 20,000 g/m²/24h Breathability

Lined with Microfleece

Customization Options:

Identity Color

Embroidery or Printing Logo

Private Label

Adjustable cuffs with hook-and-loop fasteners, Hood with drawstring

Your Custom Design

Size:

XS – 4XL, Standard or Customization Tailored Size Chart

Classic 3-Layer Hard Shell Jacket

Fabric:

100% Polyester or Nylon, 2, 2.5 or 3 Layers Construction

Water-repellent Windproof Shell Fabric

Laminated with Waterproof Breathable Membrane

Lined with TPU, Tricot

5,000 – 20,000 mm Waterproofness

5,000 – 20,000 g/m²/24h Breathability

Customization Options:

Identity Color

Embroidery or Printing Logo, Private Label

Adjustable cuffs with hook-and-loop fasteners, Hood with drawstring

Waterproof Zippers, Taped Waterproof Seams

Your Custom Design

Size:

XS – 4XL, Standard or Customization Tailored Size Chart

Let's Work Together To Create Your Custom Soft & Hard Shell Jacket

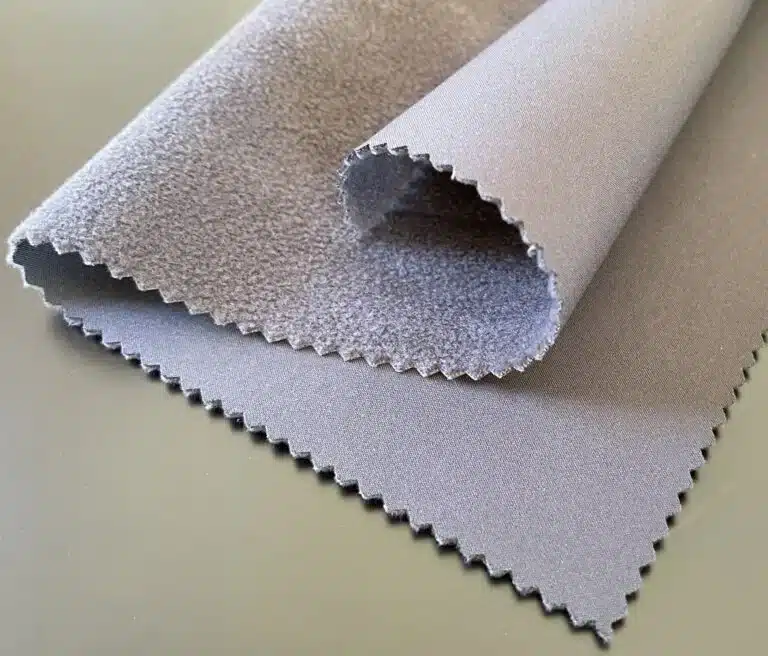

Soft Shell Fabric

Soft shell fabric is designed for flexibility, comfort, and moderate weather protection. Its regular specifications typically include:

-

Material Composition:

- A blend of polyester and spandex or elastane for stretch and durability.

- Nylon can also be used for added strength and abrasion resistance.

- Most common: 94% Polyester, 6% Spandex

-

Weight:

- Usually ranges from 280gsm to 340gsm (grams per square meter), depending on the level of warmth and protection required.

-

Layers:

- Soft shell fabric is typically made in 2-layer or 3-layer structures:

- Outer Layer: Durable, water-repellent (DWR Treatment)

- Middle Layer: Optional breathable membrane for wind resistance and waterproofness.

- Inner Layer: Brushed fleece or soft knit for comfort and insulation.

- Soft shell fabric is typically made in 2-layer or 3-layer structures:

-

- Treated with a DWR coating, ranging from 800-20,000 mm.

-

- High breathability for moisture-wicking during active use, often rated as 800-20,000 g/m²/24h.

Hard Shell Fabric

Hard shell fabric is engineered for high-level weather protection and long-term durability.

Material Composition

High-density nylon or polyester is commonly used for strength and abrasion resistance.

Stretch fibers may be added in some designs, but flexibility is not the main focus.

Common compositions include 100% Nylon or 100% Polyester.

Weight

Hard shell fabric is generally lighter than soft shell, typically ranging from 120–220 gsm, depending on construction and performance level.

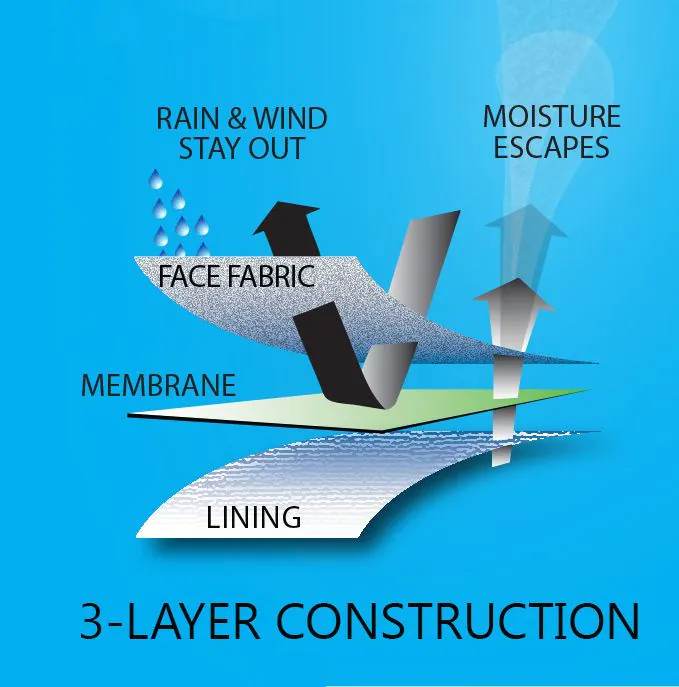

Construction

Hard shell fabric is usually made with 2-layer, 2.5-layer, or 3-layer construction:

-

Outer layer: High-density woven fabric with durable water-repellent (DWR) treatment

-

Middle layer: Waterproof and breathable membrane

-

Inner layer:

-

2-layer: Separate lining fabric

-

2.5-layer: Coated protective layer

-

3-layer: Laminated TPU, Tricot

-

Waterproofness

High waterproof performance is provided and rated between 5,000–20,000 mm.

Breathability

Breathability is maintained to reduce moisture buildup, commonly rated between 5,000–20,000 g/m²/24h.

Start Your Own Journey of Soft & Hard Shell Jacket

Find the perfect solutions of fabric & manufacturing for your own shell jackets by exploring our service & manufacturing with rich experience & high-level professionalism

A soft shell jacket is crafted using lightweight, stretchable fabrics like polyester and spandex blends, often with a Durable Water Repellent (DWR) coating. It provides comfort, mobility, and moderate weather protection.

The focus is on combining breathability and flexibility, with features like bonded layers or fleece linings for added warmth.

Precision stitching and fitted designs enhance mobility, making them ideal for active use.

The Manufacturing of

Soft Shell Jacket

&

Hard Shell Jacket

Soft shell and hard shell jackets are two essential types of outdoor apparel, but they serve different purposes, thus require different manufacuring.

The manufacturing of soft and hard shell jackets involves advanced processes to ensure performance, durability, and comfort.

Both types demand specialized equipment and expertise to meet outdoor performance standards.

A hard soft jacket requires a more technical approach. It uses laminated fabrics with waterproof membranes.

The manufacturing involves sealing seams, layering materials for strength, and ensuring maximum weatherproofing without compromising breathability.

Attention to detail in weather-resistant zippers, cuffs, and hoods is critical for creating reliable protection in extreme conditions.

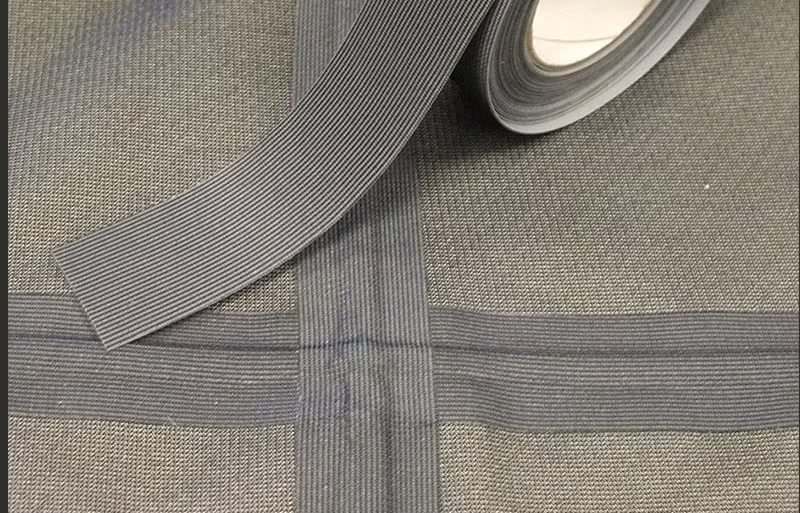

Heat-Taped Seams Sealing

Heat-taped Seams Sealing is a crucial process in shell jacket manufacturing that ensures maximum waterproof protection. During this process, a heat-activated tape is applied over the seams of the jacket, bonding the fabric layers without stitching.

This method eliminates needle holes that could allow water to penetrate, creating a completely waterproof barrier. It also enhances the jacket’s durability and maintains its lightweight profile. Heat-taped seams sealing is essential for producing shell jackets capable of withstanding heavy rain, snow, and harsh outdoor conditions while preserving breathability and flexibility.

Discover Our Commitment & Process to Quality Control

Discover our commitment to quality and rigorous quality control process for custom soft & hard shell jackets. Learn how we ensure high standard quality in every product.

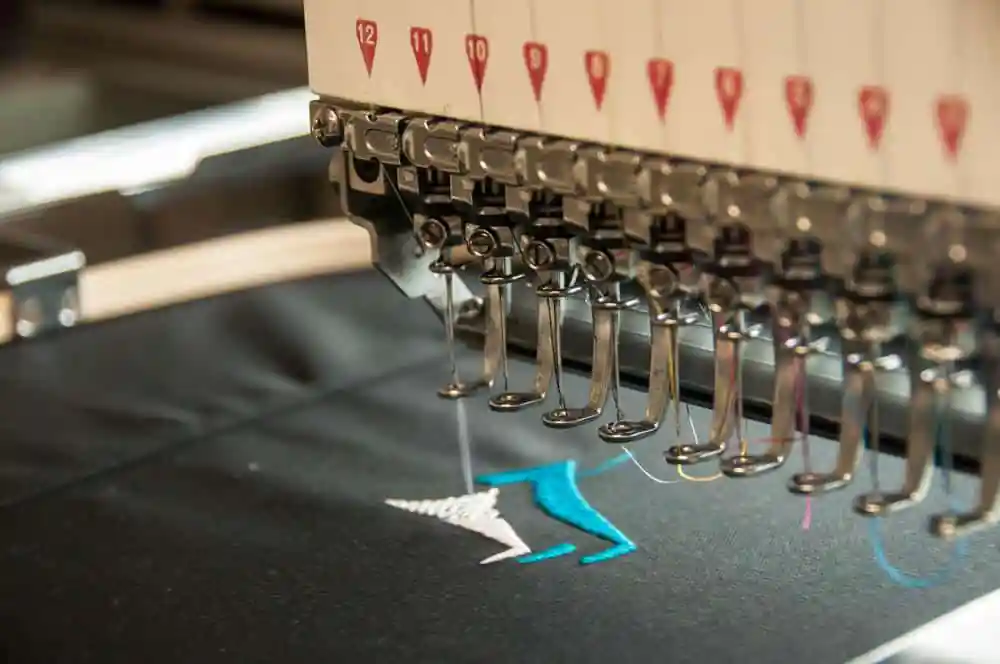

Identity Logo Solutions for Custom Soft & Hard Shell Jacket

Embroidery

Screen Print

Embossed Print

FAQ for the material and manufacturing of soft and hard shell jackets

What is the minimum order quantity (MOQ)?

MOQ depends on fabric type and color.

Soft shell jackets: usually 300 pcs per color.

Hard shell jackets: usually 500 pcs per color.

100 pcs for custom color is workable with higher cost.

You can have multi sizes within this quantity.

Are soft shell jackets fully waterproof?

No. Soft shell jackets are water-resistant, not fully waterproof. Protection is mainly provided by DWR treatment. Some membrane soft shells offer higher resistance but are still less waterproof than hard shells.

Are hard shell jackets fully waterproof?

Yes, hard shell jackets are designed to be fully waterproof. Waterproof performance depends on the membrane quality, taped seam sealing and manufacturing process.

What membrane is commonly used in hard shell jackets?

Is stretch fabric used in hard shell jackets?

Yes, but usually no. Hard shell jackets focus on protection and durability. Limited stretch may be added in some designs, but it is not standard.

What layer constructions are used in manufacturing?

Soft shell: Mostly 2-layer or 3-layer, often with a fleece inner.

Hard shell: 2-layer, 2.5-layer, or 3-layer, with laminated membrane systems.

How important is seam sealing in hard shell jackets?

Is seam sealing required for soft shell jackets?

What is the key difference between soft shell and hard shell jackets?

Different Fabrics.

Soft shell jackets are thicker, usually made from stretchy woven fabrics with polyester or nylon and spandex.

Hard shell jackets are thinner and lighter, made from high-density woven fabrics laminated with membranes.

Can custom fabric be developed?

Yes. Custom fabric can be developed for: Weight & Thickness, Stretch Level, Waterproof & Breathability Level, and Color.

Fabric development requires higher Minimum Order Quantity.

Are tests provided?

Yes.

Fabric test reports such as waterproofness and breathability rating can be provided. Finished garment tests can be arranged if required.

What customization options are available?

Customization options usually include:

Fabric type and performance level

Waterproofness and breathability ratings

Identity Color matching (Pantone available)

Identity printing or embroidery logo

Zipper, trim, and accessory selection

Fit and size grading

Package

Can size sets and pre-production samples be provided?

Yes. Size sets and PP samples can be produced before bulk production to confirm design, material, quality and fit.

Which jacket is easier and faster to manufacture?

Soft shell jackets are easier and faster to produce. Hard shell jackets require lamination control, seam sealing, and higher technical standards.

Which jacket has higher manufacturing cost?

Hard shell jackets usually have a higher cost due to:

Waterproof membranes

Seam sealing

Higher quality control requirements