Clothing manufacturing involves transforming raw materials into finished garments through processes like cutting, printing, embroidery, stitching, assembling, trimming and packing.

Understanding the type of clothing manufacturers is essential for your business success. A reliable manufacturer impacts your product's quality, cost and brand reputation. With options like CMT, FPP, OEM, ODM, Private Label and White Label, you can choose a type that aligns with your goals.

Key Takeaways

Learn about types of clothing makers: CMT, FPP, OEM, ODM, Private Label and White Label. Each type fits different business needs.

Find a manufacturer based on your goals and audience. Matching your choice to your plan gives better results.

Study makers carefully. Look at their past work, reviews, and quality. Ask for samples before deciding.

Build good relationships with manufacturers. Talking openly and showing respect makes production easier and better.

Think about your budget and minimum order quantity (MOQ). This helps control spending and stock wisely.

1. Types of Clothing Manufacturers

1.1 CMT (Cut, Make, Trim)

1.1.1 What is CMT?

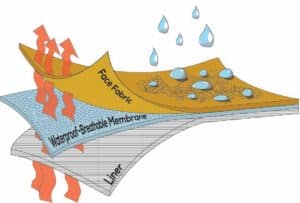

CMT, short for Cut, Make, Trim, is a manufacturing method where you, as the client, provide the materials and designs while the manufacturers handle the production process. You, as the client, are responsible for sourcing materials, including fabric and accessories. This method is common among clothing manufacturers globally due to its simplicity and flexibility.

1.1.2 Advantages of CMT

CMT offers you greater control over the production process. You can choose your preferred materials and ensure they meet your quality standards. This approach is often cost-effective, especially for businesses that already have reliable suppliers. Additionally, CMT manufacturers allow you to maintain creative freedom, making it ideal for custom clothing manufacturers.

1.1.3 Disadvantages of CMT

The responsibility of sourcing materials can be challenging. You may face delays or quality issues if your suppliers of materials fail to deliver. CMT also requires more effort from you to coordinate the entire garment manufacturing process. This can increase lead times and complicate the final garment production.

1.2 FPP (Full Production Package)

1.2.1 What is FPP?

FPP, or Full Production Package, is a comprehensive approach to apparel manufacturing, including everything from fabric sourcing to final production. This method simplifies the apparel manufacturing process for you, as the manufacturers take care of all stages of production.

1.2.2 Advantages of FPP

FPP manufacturers save you time and effort by managing the entire production process. They ensure consistency in quality and reduce the risks associated with sourcing materials. This method is convenient, especially for businesses without established supply chains. Predictable lead times also make FPP a reliable choice for custom clothing manufacturing.

1.2.3 Disadvantages of FPP

FPP services are generally more expensive than CMT. You may have less control over material selection, which could affect your brand's uniqueness. Additionally, relying entirely on the manufacturers increases your dependency on their efficiency and expertise.

1.3 OEM (Original Equipment Manufacturer)

1.3.1 What is OEM?

OEM manufacturers specialize in producing clothing based on your designs and specifications. They work on a contract basis, ensuring high-quality garment production. These manufacturers often provide additional services like prototyping, material sourcing, and quality control.

1.3.2 Advantages of OEM

OEM manufacturers offer scalability, allowing you to adjust production volumes based on demand. Their expertise ensures consistent quality, making them ideal for bulk product manufacturing. They also provide valuable advice on design and materials, helping you refine your clothing production services.

1.3.3 Disadvantages of OEM

OEM manufacturing can be costly, especially for small businesses. You may face challenges in maintaining creative control, as the manufacturer handles most aspects of production. Additionally, the reliance on a single manufacturer could pose risks if issues arise during production.

1.4 ODM (Original Design Manufacturer)

1.4.1 What is ODM?

An Original Design Manufacturer (ODM) provides pre-designed clothing that you can brand as your own. These manufacturers handle the entire process, from design to production. You select from their catalog of designs, which they provide to match your branding needs. This option is ideal if you want to launch a clothing line quickly without investing in design development.

1.4.2 Advantages of ODM

ODM manufacturers simplify the process of starting a clothing business. You save time and resources by using their ready-made designs. This approach reduces the need for extensive design expertise, making it easier for you to focus on marketing and sales. ODM also ensures consistency in quality since the manufacturer oversees the entire production process.

1.4.3 Disadvantages of ODM

Using ODM limits your creative control. You rely on the manufacturer’s existing designs, which may not fully align with your vision. This can make it harder to stand out in a competitive market.

1.5 Private Label

1.5.1 What is Private Label?

Private label clothing involves partnering with a manufacturer to produce garments under your brand name. A private label clothing manufacturer handles production, allowing you to focus on branding and selling.

Generally, you can take Private Label as OEM.

1.5.2 Advantages of Private Label

Private label allows you to build a unique brand identity by customizing existing designs. You avoid the complexities of manufacturing from scratch.

1.5.3 Disadvantages of Private Label

You might face challenges in creating a truly unique product. Additionally, your brand’s success depends heavily on the manufacturer’s reliability and quality standards.

1.6 White Label

1.6.1 What is White Label?

White label clothing involves purchasing generic, unbranded garments from a manufacturer and adding your branding. You choose from the manufacturer’s existing designs or provide minor modifications to suit your brand. White label manufacturers focus on mass production of standard designs.

Generally, you can take White Label as ODM.

1.6.2 Advantages of White Label

White label clothing is cost-effective and fast. You can quickly launch a clothing line without worrying about design or production. This option works well for businesses targeting basic or essential clothing items.

1.6.3 Disadvantages of White Label

White label clothing lacks uniqueness. Since many brands use the same designs, it becomes harder to differentiate your products. This method also limits your ability to build a strong brand identity.

1.7 Low MOQ vs. Mass Production Manufacturers

1.7.1 What are Low MOQ Manufacturers?

Low MOQ (minimum order quantity) manufacturers cater to businesses that require smaller production runs. These manufacturers are ideal for startups, small brands, or businesses testing new designs. They allow you to order fewer units, making it easier to manage inventory and reduce upfront costs. Low minimum clothing manufacturers often focus on custom clothing production, offering flexibility in design and material choices.

In most cases, the MOQ of a clothing order is decided by the MOQ of the fabric or accessories you want.

1.7.2 Advantages and Challenges of Low MOQ Manufacturers

Low MOQ manufacturers provide several benefits. You can experiment with new designs without committing to large quantities. This approach minimizes financial risk and helps you adapt to market trends quickly. Additionally, working with a custom clothing manufacturer allows you to create unique products tailored to your brand.

However, there are challenges. Smaller production runs often come with higher per-unit costs and limited customization options. Finding reliable clothing manufacturers that offer low MOQs can also be time-consuming. You may face limited options for materials or designs, as most manufacturers prioritize larger orders.

1.7.3 What are Mass Production Manufacturers?

Mass production clothing manufacturers specialize in large-scale apparel manufacturing. They produce high volumes of standardized clothing items, making them suitable for established brands or businesses with consistent demand. These manufacturers focus on the control of efficiency, quality and cost, ensuring quick turnaround times and lower costs per unit.

1.7.4 Advantages and Challenges of Mass Production Manufacturers

Mass production manufacturers offer cost efficiency. Bulk orders reduce the cost per unit, increasing your profit margins. These manufacturers also ensure consistency in quality, which is crucial for maintaining your brand’s reputation.

On the downside, mass production requires significant upfront investment. You may face challenges in managing large inventories, especially if demand fluctuates. Additionally, this approach limits flexibility, as manufacturers often prioritize standardized designs over complicated customizations.

2. Comparing Clothing Manufacturer Types

2.1 CMT vs. FPP

When comparing CMT (Cut, Make, Trim) and FPP (Full Production Package), the key difference lies in the level of involvement you have in the production process. CMT manufacturers handle only the cutting, sewing, and trimming of garments. You must source materials and manage logistics. This approach gives you more control over material quality and design but requires significant effort in coordination.

FPP manufacturers, on the other hand, take care of the entire clothing manufacturing process. They source materials, produce garments, and deliver finished products. This option saves you time and ensures consistency in quality. However, it limits your control over material selection and can be more expensive.

2.2 OEM vs. ODM

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) differ in their approach to design and production. OEM manufacturers produce clothing based on your designs and specifications. You retain full control over branding and intellectual property. This method works well if you have unique designs and want to maintain creative ownership.

ODM manufacturers, however, provide pre-designed clothing that you can add minor customization and brand. They handle both design and production, streamlining the process for you. This option is faster and less resource-intensive but limits your creative input.

The table below highlights the primary differences:

Aspect | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

Design and Intellectual Property | Focuses on manufacturing based on client’s designs and retains no design rights. | Handles both design and manufacturing, often retaining design rights. |

Manufacturing and Production | Solely responsible for production under client specifications. | Involves in both design and production, streamlining the process. |

Quality and Branding | Quality control is shared; branding is owned by the client. | Sets quality benchmarks and may own branding or allow private labeling. |

2.3 Private Label vs. White Label

Private label clothing and white label clothing cater to different business needs.

Private label clothing manufacturers produce garments exclusively for your brand. You can customize designs and specifications, allowing you to create a unique brand identity. This approach works well if you want to establish a specific brand message.

White label clothing manufacturers, however, offer mass-produced garments with minimal customization. These products are sold to multiple retailers, making them a cost-effective and quick solution for launching a clothing line.

While private label clothing provides more control and branding opportunities, white label clothing focuses on speed and affordability.

Tip: If you aim to build a distinctive brand, private label clothing manufacturers are the better choice. For businesses prioritizing cost and efficiency, white label clothing manufacturers are more suitable.

3. How to Choose the Right Clothing Manufacturer

3.1 Business goals and target market

Choosing the right clothing manufacturer starts with understanding your business goals and target market. Are you targeting high-end fashion or affordable everyday wear? Your manufacturer must align with your vision and cater to your audience's needs.

The ability to collaborate with a manufacturer who understands your needs and aligns with your business goals is essential.

3.2 Financial constraints

Your budget plays a significant role in selecting a manufacturer. High-quality production often comes at a higher cost, but it ensures better results. Compare pricing structures and payment terms to find a manufacturer that fits your financial plan.

3.3 Branding objectives

Your branding objectives influence the type of manufacturer you choose. For example, private label clothing manufacturers allow you to create a unique identity by customizing existing designs. If you prioritize creative control, consider options like CMT, OEM and Private Label manufacturers.

Choosing the right clothing manufacturer is crucial for your business success. Each type of manufacturer offers unique features tailored to different needs. For example, CMT manufacturers allow you to control fabric selection and design, while FPP manufacturers handle the entire production process for you. ODM manufacturers focus on marketing, making them ideal for new businesses.

Aligning your choice with your business goals ensures better outcomes. A manufacturer who understands your needs can maintain quality standards, improve communication, and manage flexible production volumes. Thorough research and planning help you evaluate factors like quality, experience, and lead times, ensuring a smooth clothing manufacturing process.

Tip: Take time to assess your goals and research manufacturers to build a strong foundation for your clothing business.

FAQ

What is the difference between private label and white label clothing?

Private label clothing allows you to customize designs and create a unique brand identity. White label clothing, on the other hand, involves generic products with minimal customization. Private label suits businesses aiming for exclusivity, while white label works best for quick, cost-effective launches.

How do I find reliable clothing manufacturers?

Start by researching online directories, trade shows, and industry forums. Request samples to assess quality. Check reviews and certifications to verify credibility. Building relationships through clear communication and mutual respect ensures long-term reliability.

What is MOQ, and why is it important?

MOQ stands for Minimum Order Quantity. It refers to the smallest number of units a manufacturer requires per order. Understanding MOQ helps you plan inventory and budget effectively. Low MOQ manufacturers suit startups, while mass production manufacturers cater to established brands. In most cases, the MOQ of a clothing order is decided by the MOQ of the fabric or accessories used for the clothing.

Can I negotiate with clothing manufacturers?

Yes, you can negotiate pricing, MOQs, and lead times. Approach negotiations professionally and focus on creating a win-win situation. Highlight your long-term potential as a client to build trust and secure better terms.

How do I ensure quality in clothing manufacturing?

Request prototypes or samples before bulk production. Communicate your quality standards clearly. Conduct regular inspections during production. Partnering with manufacturers who have a proven track record ensures consistent quality.

Note: Quality control is crucial for maintaining your brand’s reputation and customer satisfaction.