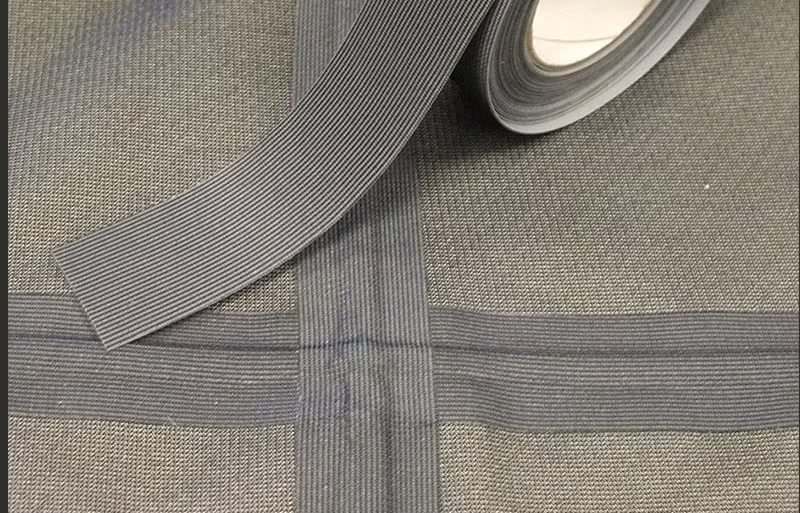

Waterproof heat taped seams solve the problem of leaking seams in outdoor clothing. Without proper sealing, even the most waterproof fabric can fail. The solution is heat-sealed tape that ensures complete protection.

Waterproof heat taped seams are created by bonding a special tape over the fabric seams using heat and pressure. This prevents water from seeping through the needle holes of sewn seams.

Heat taped seams are crucial for keeping outdoor gear and uniforms dry. Learn how they work and how to waterproof them effectively.

What are heat taped seams?

Heat taped seams are an innovative solution for waterproofing. Without taped sealing, stitched fabric seams become weak spots that allow water to penetrate. Heat Taped Sealing protects these vulnerabilities.

Heat taped seams use thermoplastic tape1 fused to fabric seams using controlled heat and pressure, creating a durable waterproof barrier.

Why are heat taped seams important?

Heat taped sealing addresses the inherent problem of stitched fabric. Needles create small holes during sewing, which compromise waterproof fabrics. By applying a specialized adhesive thermoplastic tape, these holes are sealed entirely.

Types of seams and sealing techniques

| Type of Seam | Sealing Method | Advantages |

|---|---|---|

| Flat-felled Seam | Single-sided taping | Strong and clean appearance |

| Overlocked Seam2 | Double-sided taping | Maximum waterproof protection |

| Bound Seam | Heat binding with reinforcement3 | Added durability and aesthetic finish |

Heat taped seams are especially important in harsh conditions like heavy rain or snow. This method is used in outdoor jackets, work uniforms, and sportswear to ensure dryness and comfort.

How do you waterproof tape seams?

Waterproofing seams involves precision and expertise. Even high-quality materials fail without proper seam treatment.

To waterproof tape seams, apply heat-sealable tape using specialized equipment that ensures even pressure and temperature. The tape adheres to the fabric, sealing the seam and preventing leaks.

The process of seam taping

Seam taping involves several steps:

- Preparation: Clean and align the seam to ensure proper adhesion.

- Application: Use a heat-sealing machine to apply the tape with consistent pressure.

- Inspection: Test for any gaps or loose areas to guarantee waterproofing.

Key considerations for effective waterproofing

| Factor | Impact on Waterproofing |

|---|---|

| Tape material | Determines flexibility and durability |

| Temperature control | Ensures proper bonding without fabric damage |

| Fabric compatibility | Ensures strong adhesion and no shrinkage |

By following this process, manufacturers ensure the performance of waterproof garments. This method is common in outdoor gear and safety uniforms designed for extreme environments.

Conclusion

Waterproof heat taped seams are essential for ensuring the functionality and comfort of outdoor and custom clothing. They enhance durability by sealing weak points in fabric. By understanding the methods and importance of seam taping, businesses and consumers can select high-performing, waterproof apparel.

-

Thermoplastic tape is a polymer-based adhesive material that melts when heated, bonding tightly to fabrics or surfaces to provide waterproofing, reinforcement, or structural stability. ↩

-

An overlocked seam is created using an overlocker (serger) machine, which trims, binds, and encases fabric edges in one step. This prevents fraying and adds durability, making it ideal for stretchy fabrics and seams in activewear, knitwear, and other garments requiring a clean, professional finish. ↩

-

Heat binding with reinforcement is a technique where heat-activated adhesive tapes or films are applied to fabric edges or seams. This process strengthens and seals the edges, preventing fraying and adding durability, often used in technical garments, sportswear, and outdoor gear for a clean, long-lasting finish. ↩