In the world of clothing manufacturing, precision and consistency are key to producing high-quality garments. One of the most critical tools used to achieve this is the template sew.

In this article, we’ll explore what template sew is, how it works, and why it’s essential in clothing manufacturing.

What is Template Sew?

Template sew in clothing manufacturing refers to the use of pre-designed templates or guides to achieve uniformity in sewing operations, ensuring consistent results across all garments.

It reduces human error, enhances production efficiency, and ensures every piece meets the same quality standards.

It serves as a guide for cutting, stitching, and assembling fabric pieces, ensuring that each component of the garment is consistent in size, shape, and placement.

Templates are typically made from durable materials like plastic, cardboard, or metal and are designed to match the specific measurements and design of the garment.

How Does Template Sew Work?

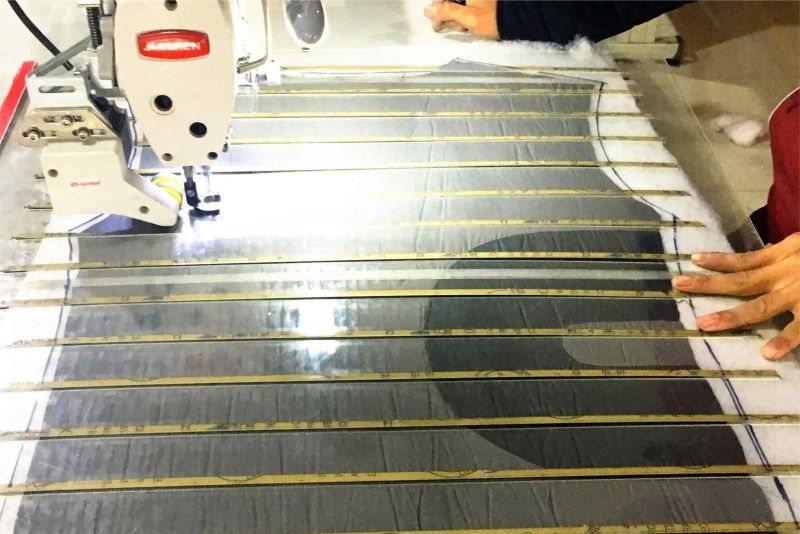

The primary tools in template sew include template molds, industrial sewing machines, and automated sewing systems. These tools work together to maintain accuracy and repeatability.

Template sewing involves several steps to ensure accuracy and efficiency:

-

Design Creation:

- The garment design is created using CAD (Computer-Aided Design) software.

- The design is broken down into individual panels (e.g., front, back, sleeves, pocket, collar).

-

Template Production:

-

Fabric Cutting:

- The templates are placed on the fabric, and the fabric is cut according to the template’s outline.

- This ensures that each piece is identical and matches the design perfectly.

-

Assembly:

- The cut fabric pieces are sewn together using the template as a guide for seam placement and alignment.

- This step ensures that the garment is assembled accurately and consistently.

Types of Templates Used in Clothing Manufacturing

Templates can vary depending on the type of garment and the manufacturing process. Here are some common types:

| Template Type | Purpose |

|---|---|

| Cutting Templates | Used to cut fabric pieces accurately according to the design specifications. |

| Sewing Templates | Guide the placement of seams, hems, and other stitching details. |

| Pocket Templates | Ensure precise placement and sizing of pockets. |

| Buttonhole Templates | Used to create consistent and accurately placed buttonholes. |

| Embroidery Templates | Guide the placement of embroidery designs on the garment. |

Why is Template Sew Important in Clothing Manufacturing?

1. Ensures Consistency

- Templates ensure that every piece of fabric is cut and sewn to the exact same specifications, resulting in uniform garments.

- This is especially important for bulk production, where consistency is critical.

2. Improves Efficiency

- By providing a clear guide for cutting and sewing, templates reduce the time needed for measuring and marking fabric.

- This speeds up the production process and increases overall efficiency.

3. Reduces Waste

- Precise cutting with templates minimizes fabric waste, making the manufacturing process more sustainable and cost-effective.

4. Enhances Quality

- Templates help maintain high-quality standards by ensuring accurate seam placement, proper alignment, and consistent sizing.

- This reduces the likelihood of errors and defects in the final product.

5. Facilitates Customization

- Templates can be easily modified to accommodate custom designs, allowing manufacturers to produce unique garments without compromising accuracy.

Applications of Template Sew in Clothing Manufacturing

Template sewing is used in the production of a wide range of garments, including:

- Down Jackets: Ensures precise placement of insulation compartments, baffles2and seams.

- Waterproof Jackets: Guides for taping seams to make jackets waterproof and windproof.

- Sportswear & Activewear: Provides accurate cutting and stitching for performance-enhancing designs. Guides for adding durability to high-stress areas like knees and elbows.

- Formal Wear: Guarantees perfect alignment of darts, pleats, and other intricate details.

Conclusion

Template sew is an indispensable tool in clothing manufacturing, ensuring precision, consistency, and efficiency in the production process. Whether you’re producing down jackets, waterproof jacket, sportswear, or everyday apparel, template sewing is a proven method for achieving excellence in garment manufacturing. By understanding and leveraging the power of template sew, manufacturers can streamline their processes, reduce waste, and deliver exceptional garments to their customers.