PBT fabric, or polybutylene terephthalate, is a kind of polyester. It is stretchy, dries quickly, and resists chlorine damage. These features make it useful in many industries. It is used in sports clothes and swimwear. These items need to be strong and flexible.

PBT is becoming more important because it is so useful. The global PBT yarn market may grow from USD 3.2 billion in 2023 to USD 5.6 billion by 2032. It has a yearly growth rate of 6.5%.

As industries change, PBT keeps showing its worth with new ideas and great performance.

Key Takeaways

PBT fabric is stretchy, strong, and resists chlorine. It is great for swimwear and sports clothes.

The need for PBT is rising worldwide. It is used in cars, clothing, and factories, showing its many uses.

PBT fabric dries fast and keeps sweat away. This makes it comfy for exercise.

PBT has many good points but costs more than other fabrics. It also harms the environment because it is made from oil.

New ways to make PBT are helping the planet. Recycling and using less energy are the main goals.

What is PBT Fabric?

Definition and Composition

PBT fabric, short for polybutylene terephthalate, is a type of polyester. It is strong, stretchy, and resists damage from the environment. This fabric is made from a plastic material that comes from petroleum. Its special structure gives it great stretch and resistance to chemicals like chlorine.

PBT fabric is softer and more flexible than regular polyester. These features make it ideal for comfortable and long-lasting products. You can find it in swimwear, sports clothes, and industrial items. It keeps its shape and lasts longer, making it a high-quality fabric.

How PBT Fabric is Manufactured

Making PBT fabric is similar to producing other synthetic fibres. Factories mix butanediol and terephthalic acid to create the material. This is melted, turned into fibres, and woven into fabric. The process is efficient and uses materials that are easy to find.

Here are some key points about how PBT fabric is made:

Aspect | Details |

|---|---|

Production Process | Similar to polyester, using common raw materials. |

Production Scale | Growing due to its excellent features. |

Energy Consumption | |

Environmental Impact | Creates less pollution and reduces waste treatment needs. |

Recycling | Can be recycled by melting and reusing the fibres. |

This process makes high-quality fabric while saving energy. For example, PBT uses less energy during dyeing, which helps it become more popular for eco-friendly production.

Comparison with Other Synthetic Fabrics (e.g., Polyester, Nylon)

When compared to polyester and nylon, PBT fabric has clear benefits. It handles heat, moisture, and pressure better. For example:

PBT can handle heat up to 140°C, while nylon struggles above 130°C.

Nylon absorbs much more water than polyester, which weakens it.

Nylon’s strength drops by 50–60% when wet, but PBT stays strong.

PBT can also be made stronger by adding glass fibres. Adding 30% glass fibre doubles its strength, making it good for tough uses. Nylon improves less under the same conditions. However, nylon is better at handling long-term stress unless it gets wet.

Sportswear and outdoor gear often use PBT fabric because it wicks moisture and keeps its shape. It is also used for durable items like backpack straps and tents, especially in adventure markets like North America and Scandinavia.

Key Properties of PBT Fabric

Elasticity and Stretch Recovery

PBT fabric is very stretchy and bounces back easily. It stretches well and returns to its shape without damage. This makes it perfect for swimwear and sports clothes. These clothes need to be flexible and comfortable.

Unlike other fabrics, PBT is highly elastic and comfy. It allows free movement and keeps its stretch for a long time. For example, in tight-fit clothes, it stays snug and doesn’t sag. Even after many uses, it keeps its shape and stretch.

PBT fabric’s stretch recovery is excellent for activewear. Whether swimming or exercising, it keeps its shape. It also supports your movements without losing form.

Durability and Longevity

PBT fabric is tough and lasts a long time. It doesn’t wear out easily, even in tough conditions. This is why it’s used in sportswear. Other fabrics like nylon or spandex break down faster. PBT stays thick and strong in the same conditions.

Here’s how PBT compares to other materials:

Feature | PBT Fabric |

|---|---|

Stretch Recovery | Excellent |

Chlorine Resistance | Lasts 5 times longer than nylon or spandex |

Quick-Drying | Yes |

UV Protection | UPF ratings between 25-39 |

Softness | Luxurious and flexible |

PBT fabric is better than many other materials. It lasts longer and works well in tough environments. This makes it great for high-performance uses.

Resistance to Chemicals and Chlorine

PBT fabric resists chemicals, especially chlorine, very well. Swimmers know chlorine can ruin swimwear quickly. But PBT handles chlorine much better than other fabrics. Swimwear made from PBT keeps its colour, shape, and stretch longer.

PBT also resists other chemicals, making it useful in factories. It works well in places with harsh substances, like filters and conveyor belts.

Choosing PBT fabric means getting a material that resists chlorine and lasts long. It’s durable and performs well in many settings.

Moisture Resistance and Quick Drying

PBT fabric is great at handling moisture and dries fast. It absorbs very little water compared to other materials. This makes it perfect for staying dry during workouts or swimming.

The fabric dries quickly because it doesn’t soak up much water. But during production, too much moisture can weaken it.

This drying process helps PBT stay stretchy and durable. For you, this means clothes made from PBT dry fast after washing or getting wet. Whether it’s swimwear or sportswear, it’s ready to wear again quickly.

PBT fabric also wicks sweat away from your skin. This keeps you dry and comfy during exercise. It’s a top choice for activewear, especially in warm or humid weather.

UV Resistance and Colour Retention

PBT fabric resists UV rays, making it great for outdoor use. Some fabrics fade or weaken in the sun, but PBT stays strong. Its design helps it handle sunlight without losing quality.

PBT also keeps its colours bright for a long time. Other fabrics may fade after washing or sun exposure, but PBT stays vibrant. This makes it ideal for swimwear and sportswear with bold colours. Your PBT clothes will look fresh even after many uses.

Because of its UV resistance and colour retention, PBT works well for outdoor furniture too. These items face a lot of sunlight, and PBT keeps them durable and good-looking. Whether by the pool or on a sunny hike, PBT fabric offers lasting protection and performance.

Applications of PBT Fabric

Sportswear and Swimwear

PBT fabric is important for making sportswear and swimwear. It stretches well and goes back to its shape easily. This makes it great for activewear, giving comfort and easy movement. You can find PBT in leggings, sports bras, and seamless clothes. Its softness and ability to keep you dry improve your experience.

Swimwear made from PBT is very durable. It resists chlorine, so swimsuits keep their shape and colour longer. Even after many swims, PBT stays strong compared to other fabrics. This makes it a top choice for both fun and competitive swimwear.

Studies show PBT is stretchier and comfier than polyester. It works well in seamless designs, making it perfect for stylish activewear. Whether swimming or exercising, PBT clothing supports your active lifestyle.

Home Textiles and Upholstery

PBT fabric is also used in home items like furniture and decorations. It lasts long and doesn’t wear out easily, making it great for sofa covers and cushions. Its UV resistance keeps colours bright for a long time.

PBT is not just pretty but also practical. It resists moisture, so furniture stays fresh and easy to clean. Curtains, cushions, and covers made from PBT improve the look and use of your home.

PBT fabric stays soft and flexible even with daily use. It’s a popular choice for homes because it mixes style with lasting quality. Choosing PBT textiles means getting products that look good and last long.

Industrial Uses (e.g., conveyor belts, filtration systems)

PBT fabric is very useful in factories because it is strong and tough. It is used in things like conveyor belts and filters, where strength and durability are very important.

Conveyor Belts

Conveyor belts made with PBT fabric are very dependable. They carry heavy items and move all the time without breaking. The fabric’s stretchiness helps the belts keep their shape under pressure. This makes them perfect for factories, food companies, and delivery services.

PBT fabric also resists damage from chemicals and oils often found in factories. This means the belts last longer and need fewer repairs. If your work uses conveyor belts, PBT fabric is a smart and long-lasting choice.

Filtration Systems

Filters made with PBT fabric work well because they resist water and chemicals. These filters are used in cleaning water, purifying air, and other factory jobs. The fabric stays strong even when exposed to harsh chemicals, keeping the filters working for a long time.

PBT fabric’s tight weave catches tiny particles but still lets air or liquid pass through. This makes it great for industries like medicine, oil refining, and food production that need top-quality filters.

Tip: Need a material that is strong, flexible, and handles tough conditions? PBT fabric is a great pick for factory use.

Advantages and Disadvantages of PBT Fabric

Advantages

PBT fabric has many benefits, making it popular in industries. It is very stretchy and bounces back well. This makes it great for swimwear and activewear, which need flexibility and comfort.

PBT is also very strong and lasts a long time. It stays in shape and works well even after heavy use. It lasts 2-3 times longer than polyester. PBT resists wear and tear, making it good for tough conditions.

PBT resists chemicals like acids and oils, so it’s useful in factories. It also protects colours from fading in sunlight. PBT dries fast because it absorbs very little water, only 0.4%. This makes it perfect for sports and outdoor clothes.

Here’s a simple table of PBT’s benefits:

Feature | Performance |

|---|---|

Long-Lasting | 2-3 times stronger than polyester |

UV Protection | Colours stay bright |

Quick Drying | Absorbs only 0.4% water |

Chemical Resistance | Handles acids and oils |

These features show why PBT is strong and reliable for many uses.

Disadvantages

PBT fabric has some downsides too. One big problem is its cost. It costs more than fabrics like polyester or nylon. This makes it harder to use for cheaper products.

Another issue is its effect on the environment. PBT is made from petroleum, which is not eco-friendly. Even though it can be recycled, making it still uses non-renewable resources. This adds to pollution and carbon emissions.

Also, making PBT needs extra care. If it gets too wet during production, it becomes weaker. This makes the process more difficult.

These problems show that while PBT is useful, it has challenges. Industries are working on ways to make it more affordable and eco-friendly.

Future Potential of PBT Fabric

Innovations in Sustainable Production

The future of PBT depends on greener production methods. Factories are finding ways to make PBT less harmful to the planet. They are using recycled materials and renewable resources. For example, recycled PBT fibres are now popular in making clothes. These fibres cut down waste and save resources. Soon, you might see more eco-friendly PBT in sportswear and home items.

New energy-saving methods are also being created. PBT already uses less energy for dyeing than other fabrics. Now, new ideas aim to lower energy use and pollution even more. This makes PBT a great choice for industries that care about the environment.

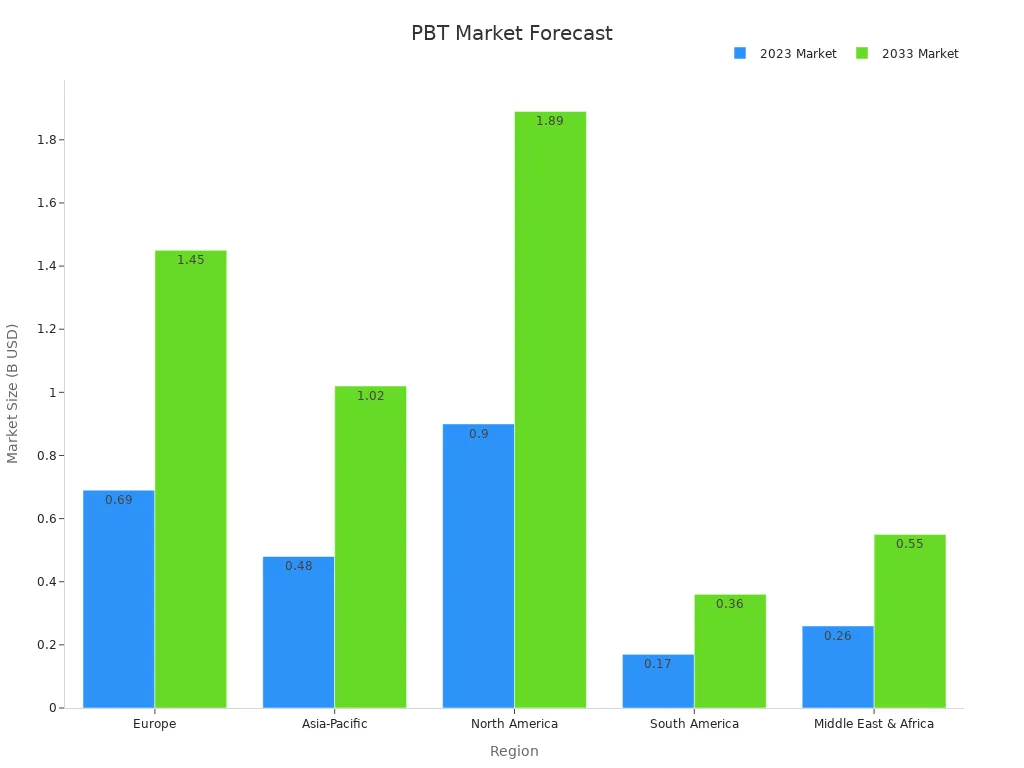

The global PBT market is growing because of these changes. For example, Europe’s PBT market may grow from USD 0.69 billion in 2023 to USD 1.45 billion by 2033. This growth is driven by eco-friendly efforts and advanced car materials. Other areas like Asia-Pacific and North America are also seeing more demand for PBT in cars and electronics.

Expanding Applications in Emerging Industries

PBT is being used in new and growing industries. Its strength, stretchiness, and chemical resistance make it useful in many ways. In farming, PBT is used in nets and ropes to help modern agriculture. It is also found in medical tools where high-quality materials are needed.

In clothing, PBT is now a key material for eco-friendly fashion. Its quick-drying and sun-resistant features make it perfect for outdoor and sports clothes. Electronics companies also like PBT because it handles heat and pressure well. These qualities keep PBT useful in many industries.

Sector | Application Description | Growth Drivers |

|---|---|---|

Agriculture | Growth in modern farming technology | |

Textiles | Used in eco-friendly clothes and fabrics | Focus on sustainable production |

PBT fabric is known for being stretchy, strong, and resistant to chemicals and sunlight. These qualities make it great for sports clothes. It is versatile and keeps you dry, offering both comfort and performance. But, it costs more to make and doesn’t handle high heat well.

Advantages | Disadvantages |

|---|---|

Strong and doesn’t tear or stretch easily | Weak when exposed to high heat |

Handles chemicals well | Colours may fade over time |

Protects against damage from sunlight | Can form small fabric balls |

Keeps moisture away from the skin | Costs more to produce |

Soft and comfy | N/A |

Useful in many ways | N/A |

Eco-friendly | N/A |

With new ideas, PBT fabric could become even better for eco-friendly and varied uses.

FAQ

What makes PBT fabric special compared to normal polyester?

PBT fabric is stretchier and keeps its shape better than polyester. It resists chlorine and sunlight, making it great for swimwear and outdoor clothes. Polyester doesn’t have these qualities and wears out faster in tough conditions.

Can PBT fabric be reused?

Yes, PBT fabric can be reused. Factories melt the fibres and turn them into new items. This helps reduce waste and supports eco-friendly practices.

Is PBT fabric good for people with sensitive skin?

PBT fabric is soft and smooth, so it feels nice on sensitive skin. It also keeps you dry by moving sweat away, which helps avoid irritation during activities.

How does PBT fabric react to sunlight?

PBT fabric blocks UV rays and keeps its colours bright even after long sun exposure. This makes it a great choice for outdoor clothes and furniture.

Why does PBT fabric cost more than other synthetic fabrics?

PBT fabric is more expensive because it’s stretchy, strong, and resists chemicals. Its production needs extra care to keep its quality, which adds to the cost.