Currently, during the peak season for outdoor activities, outdoor apparel that combines functionality with fashion sense has undoubtedly become a key market focus. With in-depth research on fluorine-based compounds, the call to remove PFAS (Per- and polyfluoroalkyl substances) is growing louder. Traditional outdoor equipment like waterproof jackets and hiking boots have long relied on PFAS for water and oil repellency, but at the potential cost of harm to ecosystems and consumer health. An innovation-driven sustainable transformation is emerging – a growing number of pioneering brands are developing eco-friendly PFAS-free alternatives, redefining the standards of "high performance."

I. How to Identify PFAS-Free Products

Currently, there is no unified "PFAS-Free" certification label in the market, making it difficult for consumers to identify truly eco-friendly products. However, some responsible companies have begun voluntarily labeling products as "PFAS-Free" to state their position. Furthermore, consumers can check product ingredient lists to avoid items containing "PTFE" (Polytetrafluoroethylene) or terms like "fluoro" (indicating fluorinated compounds). Some international eco-certification systems – such as bluesign®, Oeko-Tex®, and Green Shape – are also promoting the establishment of PFAS-free standards. A growing number of brands, not only from the outdoor industry but also from apparel, home goods, and even food packaging, are publicly committing to reducing or completely phasing out PFAS use.

II. Global Actions in the Fight Against PFAS

Completely phasing out PFAS is feasible but requires systematic planning, supply chain transparency, and industry-wide collaboration. Currently, multiple countries and regions have begun taking action to restrict the proliferation of PFAS. For example, the EU has listed PFAS compounds like PFOA, PFOS, and PFHxS as "Substances of Very High Concern" (SVHCs), requiring strict authorization for their use. However, a globally unified solution remains a distant goal – in many countries and regions, even labeling requirements for PFAS-containing products have not yet been established.

1. Legislation Leading the Way: Policy-Driven Industry Transformation

The European Green Deal is driving a series of regulations impacting the entire textile and apparel industry, which neither outdoor equipment nor other market segments can avoid. Brands are setting carbon reduction targets, but these environmental commitments extend beyond carbon emissions to broader sustainability goals like reducing water consumption and eliminating toxic chemicals. These issues have gained continuous momentum in recent years and form the core of new regulations.

2. Three Key Legislations Reshaping Industry Rules

(1) Ecodesign for Sustainable Products Regulation (ESPR)

The "Safe and Sustainable by Design" chapter explicitly states that the design of any chemical product or textile material must not involve the use of toxic substances. This cuts off the possibility of PFAS use at the source.

(2) Revised Waste Framework Directive

Requires that all waste must be processed domestically, prohibiting cross-border transportation. This rule will strongly boost the circular economy and force companies to improve product design.

(3) Green Claims Directive

Any environmental claim must undergo third-party verification, thoroughly putting an end to greenwashing and ensuring consumers receive reliable and truthful environmental information.

III. Overview of PFAS Alternatives from Global Outdoor Brands

PFAS have long been used by outdoor brands in products like waterproof jackets and tents due to their excellent water and oil repellency. However, as their environmental persistence and health hazards are confirmed, the global outdoor industry is accelerating the phase-out of PFAS and exploring safer alternatives. Currently, several brands have successfully developed high-performance PFAS-free products, proving that environmental protection and functionality can coexist.

1. Patagonia: Made Without PFAS for the Spring 2025 season and beyond

In Fall 2019, Patagonia launched the first products with DWR finishes made without intentionally added PFAS, and in 2021, Patagonia introduced the Men’s and Women’s Dual Aspect Jacket and Bibs, which were also made without intentionally added PFAS for the DWR coating as well as the water-repellent membrane.

For the Spring 2025 season and beyond, 100% of our new products are made without intentionally added PFAS. That means Patagonia do not add fluorinated chemistries to achieve a specific function or technical feature in our gear.

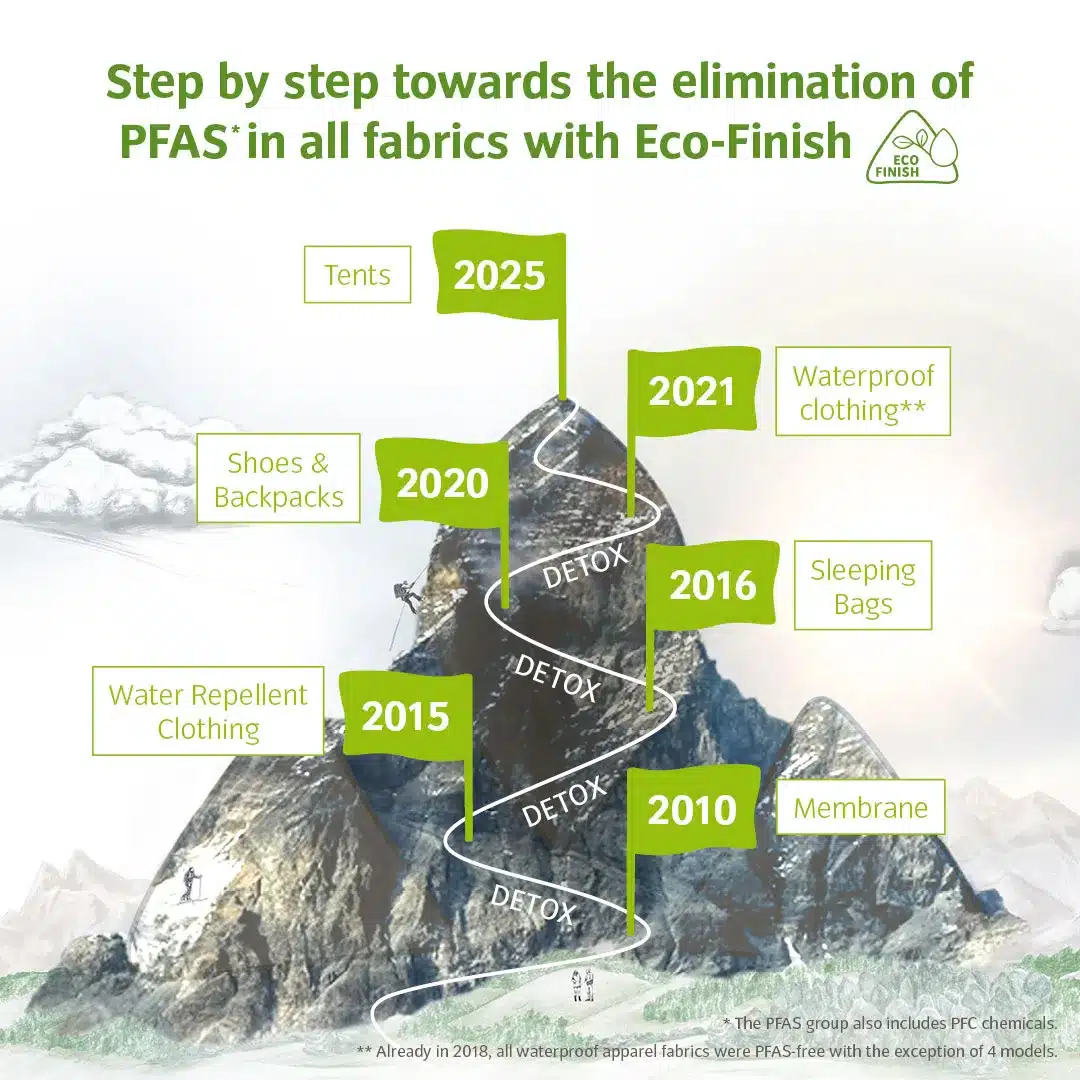

2. VAUDE: Aiming for a complete product line to be PFAS-free by 2025

The German brand VAUDE is a pioneer in sustainable outdoors. Its clothing, sleeping bags, backpacks, and shoes are already completely PFAS-free, with plans to find eco-friendly alternatives for tents by 2025. The brand uses bluesign® certified fabrics and ensures products meet strict environmental standards through its Green Shape label.

3. Fjällräven: Over a Decade of PFAS-Free Commitment

The Swedish brand Fjällräven abandoned PFAS over ten years ago, saying no to PFA'S since 2009, collaborating with the Swedish Chemical Group to establish strict chemical management policies ensuring all products (including rainwear and backpacks) are free of fluorocarbons.

4. Norrona: Target to Achieve PFAS-Free Status by 2025

The Norwegian brand Norrona is gradually phasing out PFAS, aiming to transition its entire product line to fluorine-free alternative materials by 2025.

5. Jack Wolfskin: Completely Abandoned PFAS in 2019

Jack Wolfskin became a bluesign® system partner in 2011 in order to restrict the chemicals used during the manufacturing process.

6. Anta's Second-Generation Membrane: Fully Bio-Based Material

The Chinese brand Anta has developed a second-generation waterproof membrane utilizing fluorine-free Durable Water Repellent (DWR) technology that complies with EU REACH regulations. This technology forms a nano-level protective layer on the fabric surface, causing liquids (like water) to bead up and roll off upon contact, while maintaining fabric breathability, thus balancing environmental protection with performance. Anta's second-generation membrane has been applied in its high-end outdoor equipment, such as the Aerovent Zero Storm Mecha series.

Challenges and Future Outlook

Despite breakthroughs in alternative technologies, the cost of some PFAS-free materials remains relatively high, and performance in certain extreme environments still needs optimization. Furthermore, supply chains for new materials are not yet fully mature; stable raw material supply and scalable production remain industry pain points. Industry predictions suggest that with expanded production scale and technological iteration, the cost of PFAS-free materials is expected to decrease to acceptable levels within the next 3-5 years, while the performance gap is also anticipated to narrow significantly within the same period.

Conclusion

However, before more advanced technologies are developed, it's worth pondering: Are our demands for clothing's waterproofing, windproofing, and even sun protection somewhat exaggerated? When we pursue ultimate standards and functions, is the environment we depend on paying the price? Caught between the allure of high-performance products and the social responsibility of environmental stewardship, many brands are navigating a difficult path.