Outdoor clothing must remain comfortable, safe, and durable in rain, snow, cold wind, intense sunlight, and high-friction environments. This article explains the shell fabrics, insulation, and base-layer materials used in clothing systems, along with sustainability trends, focusing on leading brands, technical backgrounds, material structures, and typical applications.

Functional Synthetic Fabrics (Shell Layer)

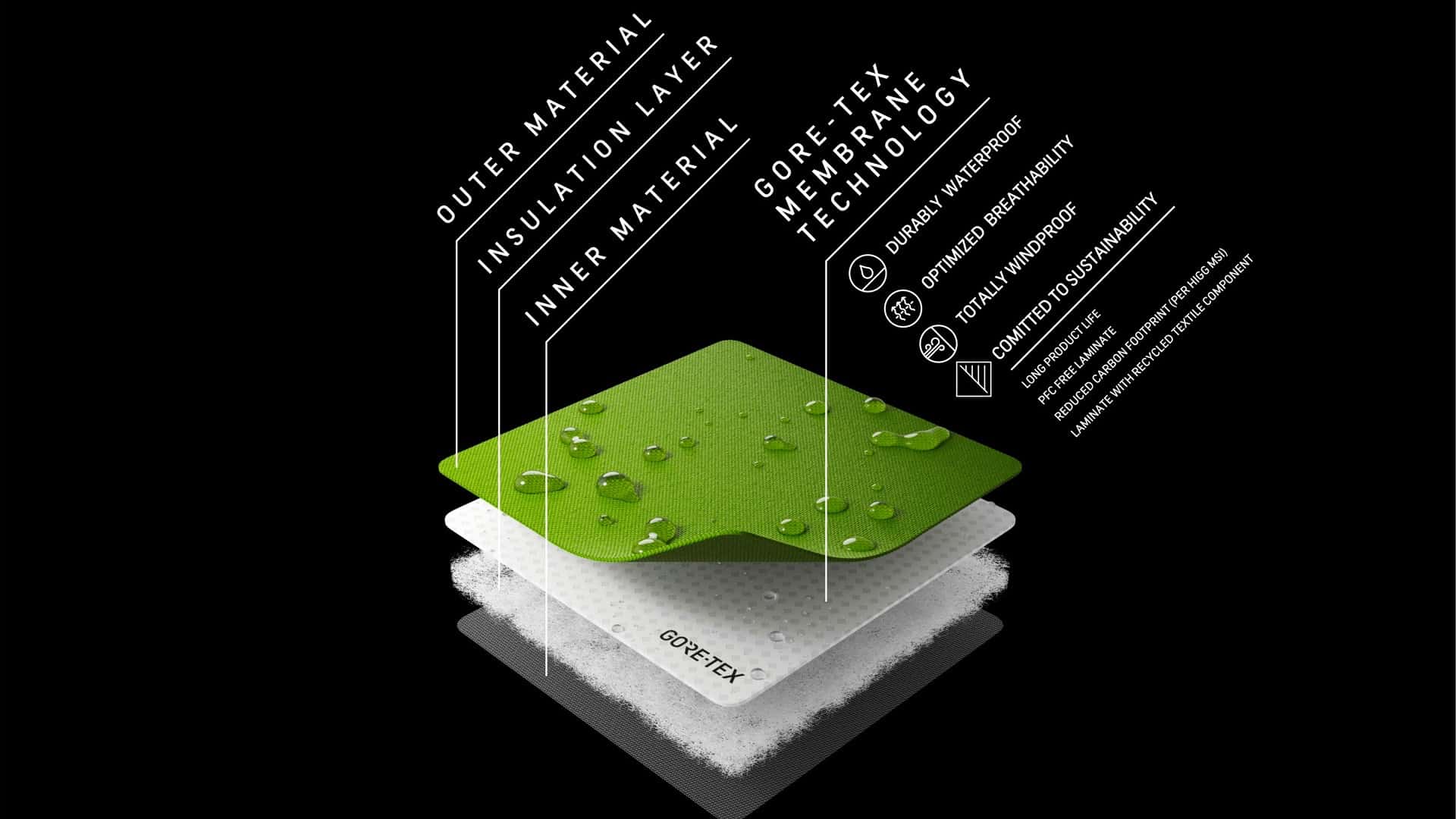

GORE-TEX®

GORE-TEX is a groundbreaking waterproof, breathable fabric technology that has set the global standard for performance outerwear.

GORE-TEX began in 1969 when Robert W. Gore, son of company founder Wilbert L. Gore, discovered that heated PTFE could be rapidly stretched into a strong, microporous structure. This expanded PTFE (ePTFE) became the core material behind the waterproof and breathable GORE-TEX membrane. The invention marked a major milestone for W. L. Gore & Associates and laid the foundation for the GORE-TEX brand used across outdoor, industrial, and military products.

Today, GORE-TEX products are engineered for a wide range of demanding activities, from mountaineering and hiking to tactical operations, maintaining an unparalleled reputation for protection and durability in extreme conditions. The technology is implemented not only in outdoor clothing, but also in footwear, gloves, and headwear.

The core material of “Gore-Tex” is expanded PTFE (ePTFE). Made from PTFE polymers and expanded to create a microporous structure, ePTFE becomes extremely thin while maintaining strength, integrity, and flexibility. Beyond apparel, ePTFE is also used in medical devices requiring long lifespan and controlled porosity.

- Durably Waterproof

- Really Breathable

- Totally Windproof

Many leading manufacturers of high-performance outdoor jackets incorporate GORE-TEX technology into their products. Notable examples include Arc'teryx, Burton, Mamut, Norrøna...

Its “triple protection” (waterproof / windproof / breathable) membrane helped make hardshell jackets, ski wear, and mountaineering boots true “all-terrain warriors.”

Pertex®

Pertex® is a British brand founded in 1979, known for being "extremely lightweight".

Pertex is a leading fabric brand specializing in high-performance, lightweight textiles for outdoor and adventure sports. The brand's history reflects a focus on specialized fabric engineering:

- Key Advantage:

Pertex fabrics are renowned for their exceptional balance of minimal weight, high water resistance, and superior breathability, achieved through precise yarn construction and advanced finishing techniques.

Today, Pertex fabrics are widely used in premium down insulation, shell jackets, and equipment where weight-to-performance ratio is critical.

- Quantum

Pertex Quantum uses a tightly woven structure to provide a light and soft downproof fabric that allows insulation to fully loft, providing both comfort and enhanced thermal performance.

Precisely constructed from incredibly fine yarns, Pertex Quantum fabrics are designed to trap still air and improve the efficiency of insulation. A durable water repellent (DWR) finish sheds light rain and snow to provide additional weather protection.

- Shield

Pertex Shield fabrics are a system comprised of woven face fabric, membrane and optional backer. These elements are available in a variety of options and numerous combinations, each with specific performance attributes, Waterproof, Breathable, Windproof, Lightweight, Soft, Packable.

eVent®

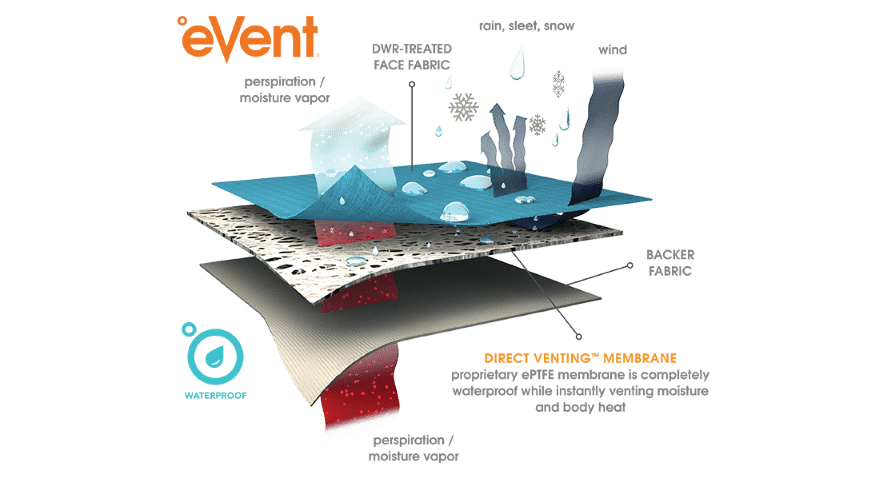

Founded in 1999, eVent® Fabrics innovates reliable, high-performance weather protection laminates and membranes that defy the elements.

The first to introduce Direct Venting™, meaning its ePTFE membrane can vent perspiration without needing moisture saturation. Popular for hiking, cycling softshells, and windbreaker jackets.

Schoeller® Series

The highest quality, sustainability, functionality, long service life, durability, and modern designs and feelgood comfort signify schoeller® stretch fabrics for the outdoor industry.

Swiss company Schoeller has provided multi-functional composite textiles for outdoor jackets and urban performance apparel since introducing the world's first elastic skipants in 1961.

- schoeller®-dynamic - Comfort in all seasons and in every application

schoeller®-dynamic are comfortable allround functional fabrics. Characterized by durability, freedom of movement and a high level of clothing comfort, makes schoeller®-dynamic the preferred fabric for technical apparel. The different colour versions can be used in summer and winter wear.

- schoeller®-dryskin - The performance promoting double fabric construction

The double fabric construction developed especially for active sports consist of synthetic fibres on the outside and functional fibres on the inside for rapid moisture transport. This supports physical performance capacity during sporting activities.

- Schoeller®-naturetec - Natural fibres with practical function

Schoeller®-naturetec is the unique soft-shell combination of soft, natural fibres and functional materials. The ideal companion for all outdoor activities where freedom of movement and a good body temperature are equally important, schoeller®-naturetec is exceptionally hard wearing, pleasantly soft, lightweight and kind to the skin.

- Schoeller®-wb-400 - The all in one soft-shell

The soft-shell classic for year-round use. Two textile surfaces are bonded with a highly breathable coating in a special process. The coating in the middle ensures additional protection from wind and water. This produces soft-shellfabrics for the most varied of requirements and for every season.

- Schoeller®-wb-formula - Water and windproof comfort

Light two and three layer construction with a water and windproof, elastic and moisture vapor permeable membrane. WB-formula provides protection from wind and rain while simultaneously allowing water vapor to escape to the outside. The elastic membrane permits the development of stretch fabrics with the highest level of clothing comfort.

Polartec®

Polartec's origins go back to Malden Mills, which developed the first synthetic fleece in 1981, marketed under the name PolarFleece®. Later, in 1991, the company formalized the Polartec brand around that innovation, and as the pioneers of fleece, Polartec creates insulated fabrics that keep people comfortable and warm whatever the conditions.

The latest Power Shield™ RPM (100% recycled) and Power Shield™ Pro (partially bio-based) offer waterproof performance and recyclability, making softshell jackets lighter and more sustainable.

Polartec® Power Shield™ RPM is a revolutionized weather protection fabric for high-intensity activity. The extremely breathable and resilient membrane construction provides high-stretch, 10k/20k weather protection and comfort [10k mm water resistance (ISO 811) & 20k g/m²/24hrs breathability (JIS L1099, B1)]. Made to reduce our impact on the planet and to enable circular processes, with the use of 100% recycled polyester fiber contents and styles containing the recycled polyester membrane.

Polartec® Power Shield™ Pro is an expedition-grade waterproof technology made for the wet outdoors. Engineered for mountain conditions, its highly durable, highly breathable, non-PFAS monolithic membrane provides 20k/20k breathable waterproof protection that stands up to the harshest environments.

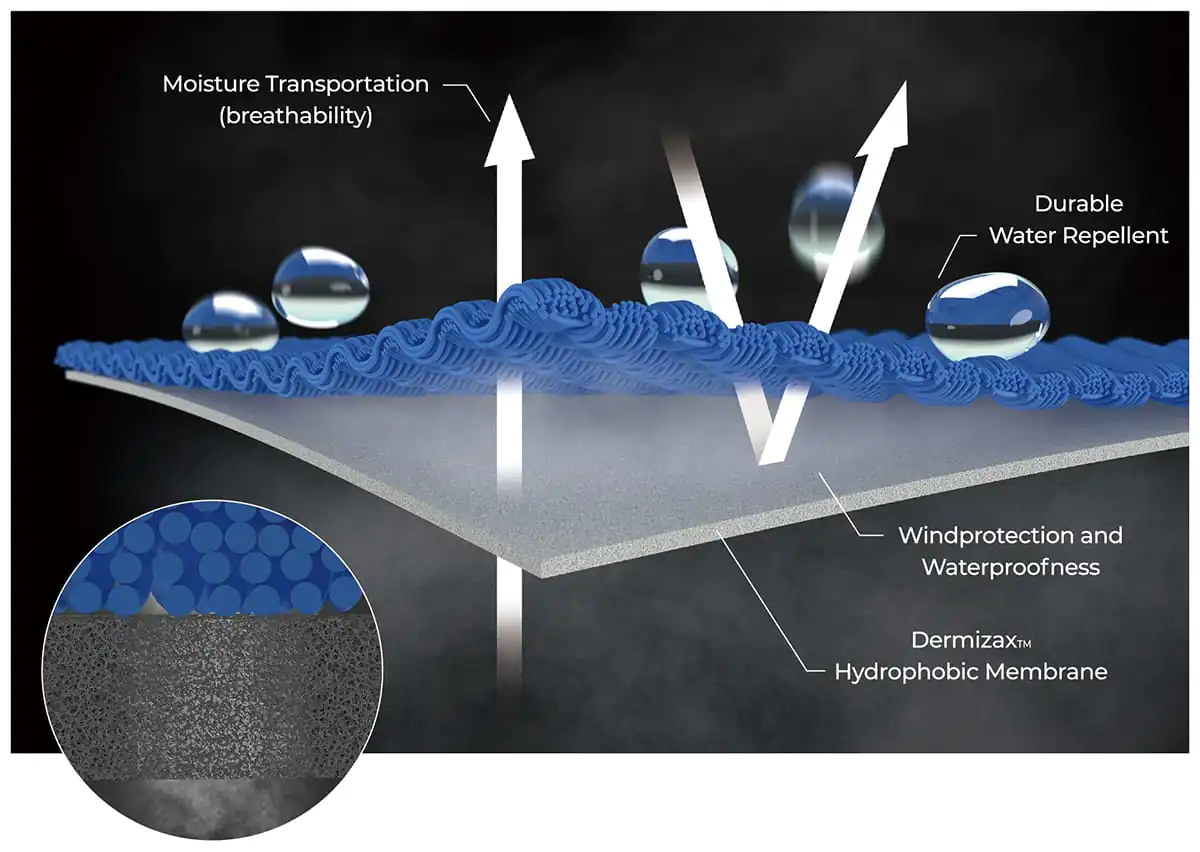

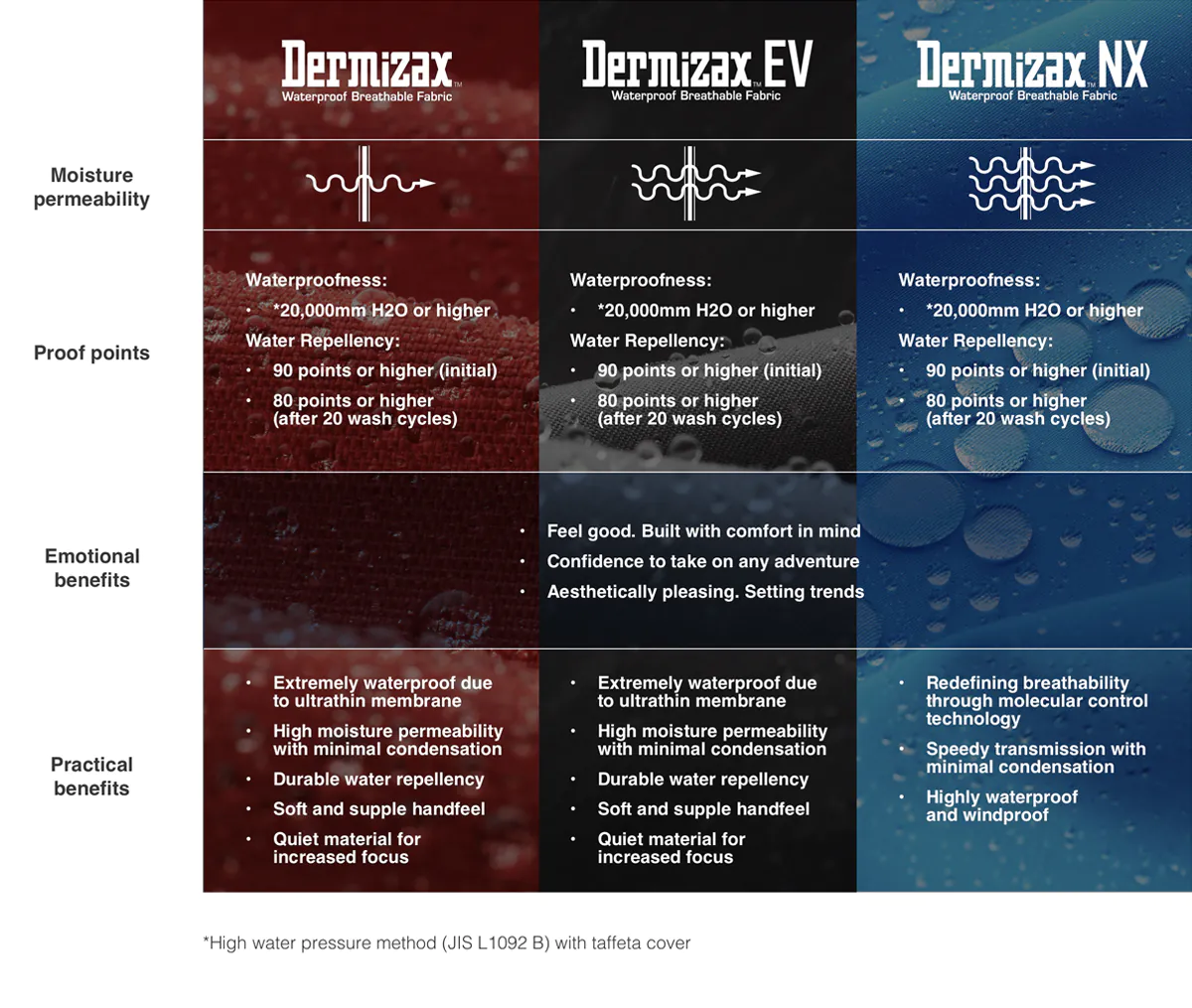

Dermizax™

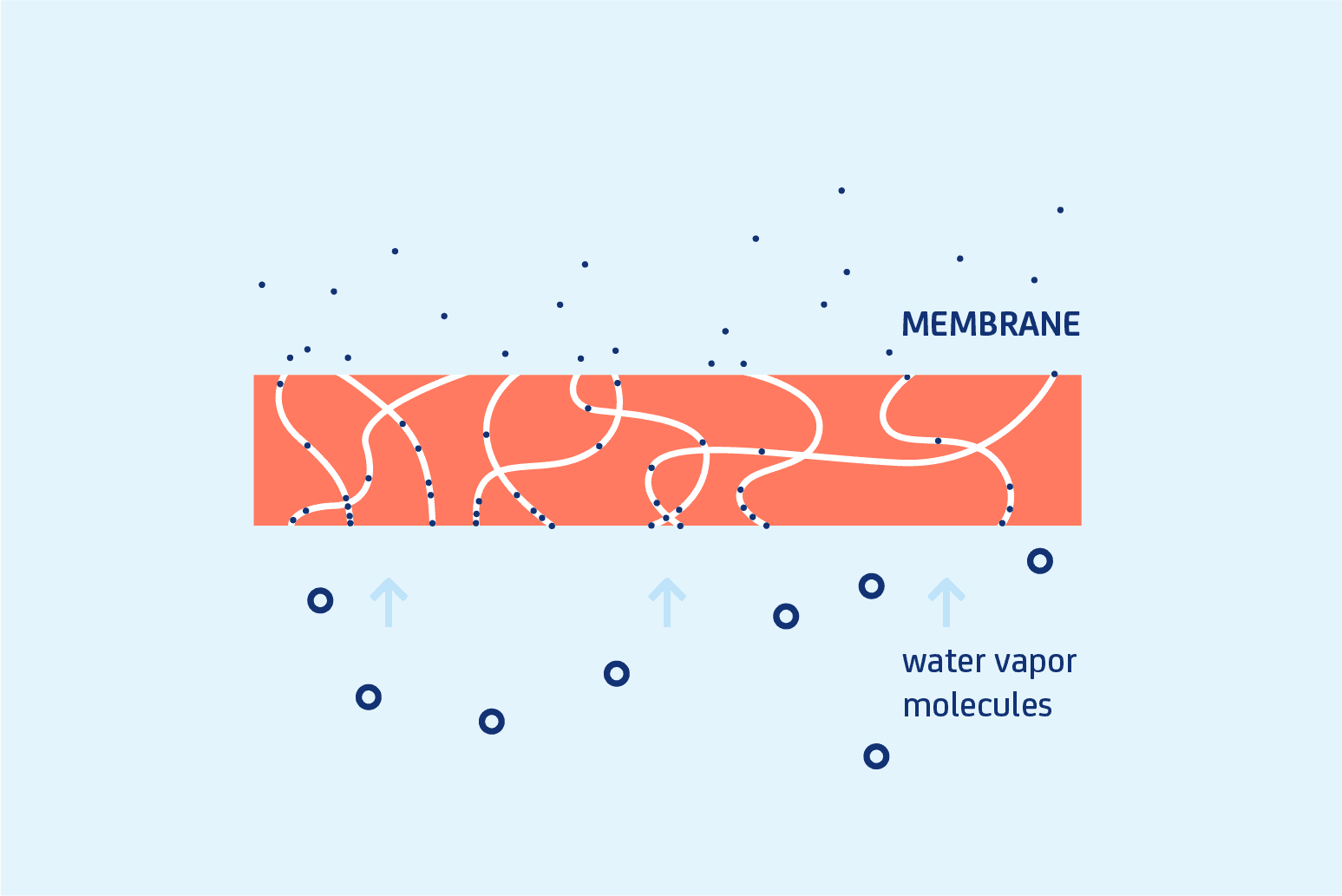

Dermizax™ is a high-performance waterproof and breathable membrane technology developed by Toray Industries, Inc., a leading Japanese chemical company. It uses a non-porous hydrophilic polyurethane (PU) membrane that provides stretch, excellent moisture transport, and strong resistance to condensation.

Dermizax™ is a fabric with a highly sophisticated and technical membrane that achieves the highest level of waterproofness, breathability and resistance to condensation, while maintaining outstanding flexibility and durable comfort, achieved through precise molecular control of polyurethane-based films.

The fabric is stretchable, adaptable and flexible. Today, Dermizax™ technology is widely used in premium skiwear, outdoor jacket, and functional sportswear, offering reliable protection and comfort in diverse weather conditions through its EV and NX variants tailored to different activity levels.

Whatever sport you choose, Dermizax™ can adapt and protect you from the worst that nature can throw at it while you remain comfortable and in control.

Sympatex®

Since 1986, Sympatex's membrane has been a benchmark for the sport and outdoor textile industry, as well for the workwear sector.

Hydrophilic, i.e. water-loving, molecular chains in Sympatex's membrane absorb the water vapor and discharge it to the outside. The higher the temperature and humidity difference, the greater the effect. Thus, Sympatex's membrane works dynamically and adapts perfectly to the conditions. At the same time, it does not allow water or wind to penetrate from the outside and protects the body from any weather.

Sympatex produces recyclable membranes for sustainable outdoor clothing.

Stormfleece™

Stormfleece™ was developed by SINGTEX in 2017. Stormfleece™ is a technical fabric technology specializing in weather-resistant insulation, known for its unique combination of warmth and weather protection.

- ONE-LAYER ENGINEERING

STORMFLEECE™ is Singtex®'s patented technology that creates a fabric with wind and rain-resistant outer layer and soft, warm inner layer by combining woven fabric with fleece technology.

It integrates a windproof and water-resistant membrane directly bonded to premium fleece, creating a single fabric that provides both insulation and protection without the need for separate layering.

Used in place of traditional knitted 2-layer soft-shells, the single-layer product harnesses both toughness and suppleness and reduces material consumption, while its densely woven structure minimizes the problem of environmental pollution caused by fibers falling or peeling off, offering better wind resistance and durability.

With its single layer construction, STORMFLEECE™ is lighter and less bulkier compared to 2 or 3 layer fabrics.

Insulation & Thermal Regulation Materials (Mid Layer)

PrimaLoft®

Warm - even when wet, Packable, Lightweight

PrimaLoft® was originally developed in 1983 by Albany International Corporation in response to a contract from the U.S. Army, which sought a synthetic insulation that could mimic down's warmth and compressibility while performing in damp conditions.

Today, Primaloft is widely used in outdoor jackets, gloves, footwear, and sleeping bags, establishing itself as the benchmark for warm, lightweight, and water-resistant synthetic insulation.

- PrimaLoft® Active:

Breathable, moisture managment, stretch. PrimaLoft® Active was developed to keep you comfortable in a wide range of activities, regardless of intensity or season.

- PrimaLoft® ThermoPlume®:

ThermoPlume® is a vegan-friendly alternative to down. Designed to mimic down with lightweight warmth, loft, softness and compressability. As a bonus, it’s made from 100% recycled content and features fluorocarbon-free water resistance.

- PrimaLoft® P.U.R.E.™:

P.U.R.E. stands for Produced Using Reduced Emissions. PrimaLoft® P.U.R.E.™ is a manufacturing method that drastically reduces emissions more than 50% during the production of synthetic insulation.

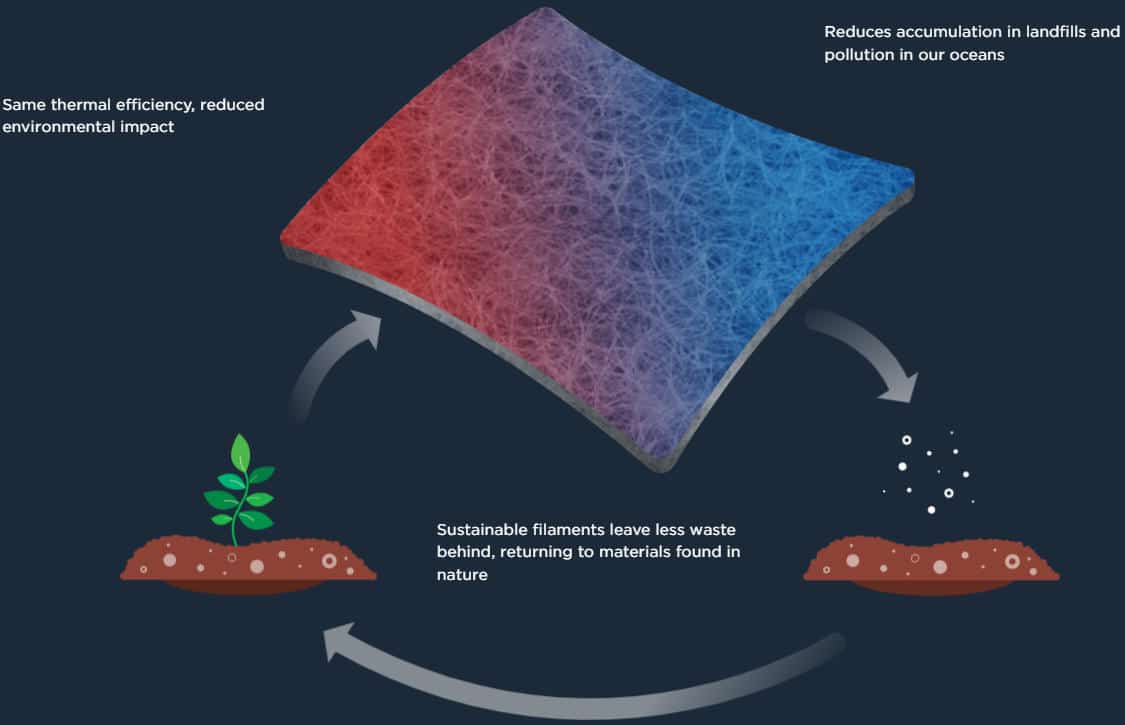

- PrimaLoft® Bio™:

PrimaLoft® Bio™ fibers are designed to return to materials found in nature. This helps reduce the long-term impact of microplastics. PrimaLoft® Bio™ fibers break down at a highly-accelerated rate in landfills, oceans and wastewater.

- Aerogel & Cross Core™:

Aerogel is a material originally pioneered by NASA and harnessed by PrimaLoft. PrimaLoft use it to give a temperature barrier that locks out extreme cold and heat. It is the lightest solid known to man - providing revolutionary lightweight warmth.

For the first products within PrimaLoft® Cross Core™ platform, PrimaLoft infused PrimaLoft materials with aerogel that was orginially developed by NASA for aerospace applications. Aerogel is the lightest solid material on earth - comprised of more than 95% air. To produce the insulation, particles of aerogel are embedded into the PrimaLoft fiber itself, delivering enhanced lightweight warmth.

3M™ Thinsulate™

Thinsulate™ insulation was developed by 3M Company and first introduced in 1979.

Thinsulate™ is an innovative, animal-free synthetic insulation. Its loose-fill fibers mimic the softness and loft of natural down when dry, and maintain warmth far better than down when wet.

Made from extremely fine microfibers, it traps air efficiently and reduces radiant heat loss while still allowing moisture to escape, keeping the wearer warm and comfortable in varied conditions.

Climashield®

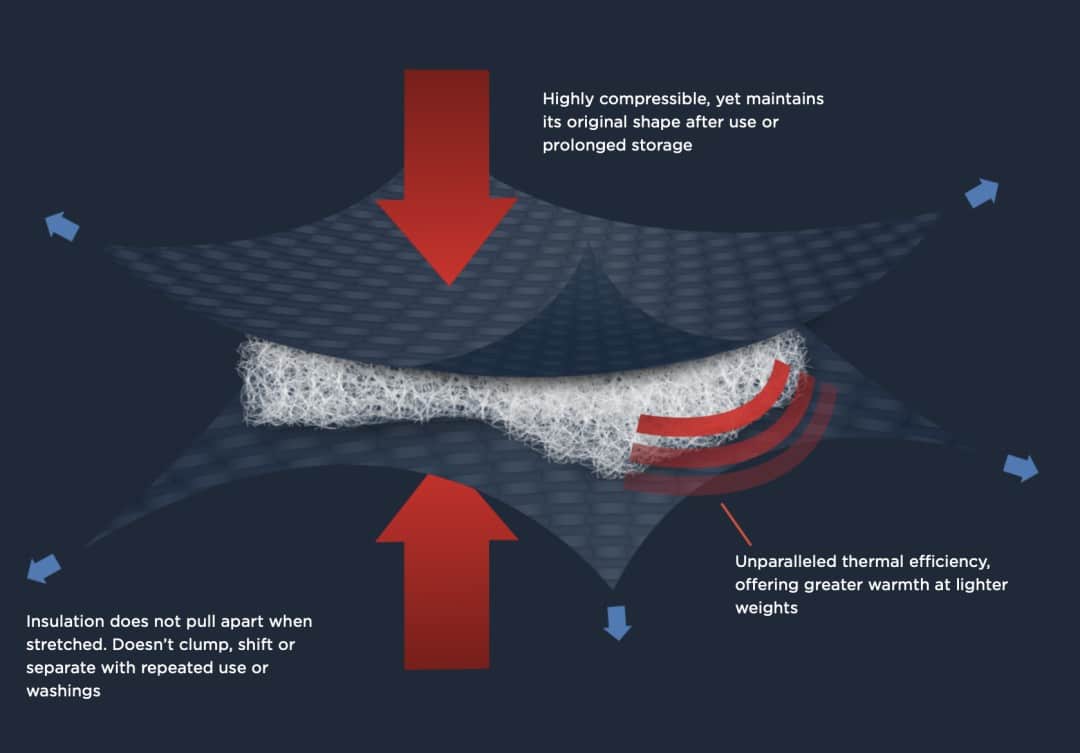

Climashield® is the world leader in the manufacture and development of continuous filament insulation, that resists breakage and migration, offering durability and wash resistance.

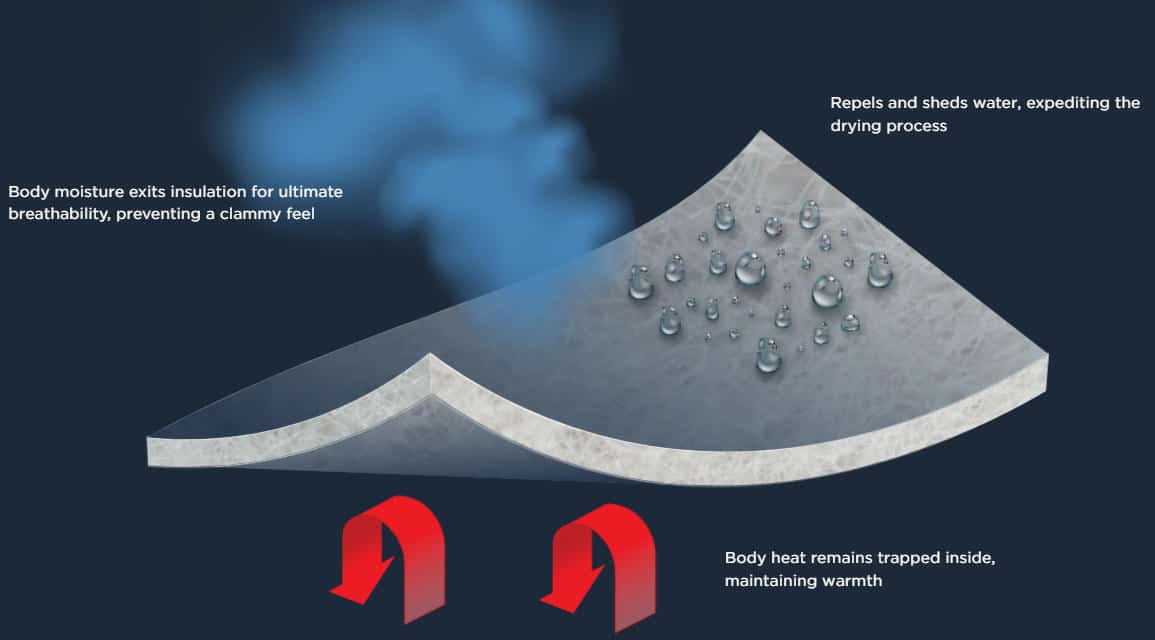

- AquaBan®

AquaBan® is a proprietary surface encapsulation treatment designed to minimize the impact of moisture on warmth and to enhance the passage of moisture out and away from the body. this technology ensures warmth in wet and humid conditions.

- FR (Fire Resistant)

Climashield®'s FR technology acts as a barrier against cold temperatures and flame exposure, specially crafted for strenuous environments where protective components are paramount to safety. Berry compliant, the technology is applied to insulation for military applications, including outerwear, sleeping bags, and shelters, as well as workwear.

- Climashield® 360

Using sustainable filaments, this planet-friendly upgrade is designed to return back to its origins in nature at the end of its product life cycle.

Base Layers: Moisture-Wicking & Thermoregulation

Polartec® Power Dry™

Polartec® Power Dry™ is an all-weather base layer, built to quickly wick moisture away from skin to outer layers during activity. A highly breathable and fast-drying fabric, this lightweight bi-component knit material is comfortable next-to-skin, preventing saturation and regulating temperature with efficient moisture management technology.

Polartec® Power Stretch™

Polartec® Power Stretch™ is an agile shape retaining, 4-way stretch fabric. Engineered for resilience and comfortable warmth with a low-friction, highly breathable and moisture wicking dual surface.

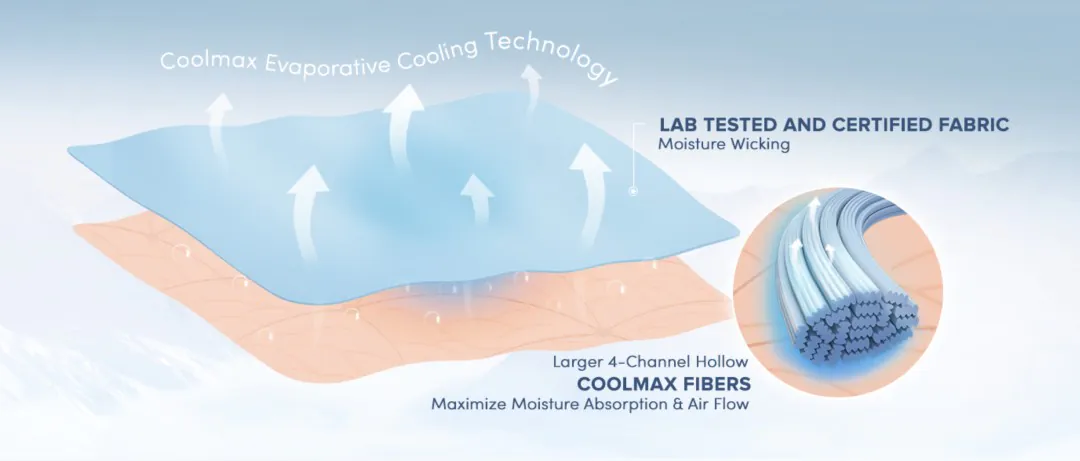

COOLMAX®

CoolMax™ was originally developed by DuPont Textiles & Interiors in 1986. After DuPont spun off its textile division into Invista, the CoolMax brand moved to Invista. In 2019, Invista sold its Apparel & Advanced Textiles business (including CoolMax) to Shandong Ruyi, resulting in the creation of The LYCRA Company, which now owns the CoolMax brand.

Merino Wool

Merino wool comes from merino sheep raised in Australia and New Zealand.

Merino wool is soft and pulls sweat away from your skin. Merino wool is special because it’s light but very warm. Its wavy fibers add warmth while still letting air flow. Wool clothes, like base layers, are perfect for layering in cold weather.

Coatings, Abrasion Resistance & Protective Fabrics

CORDURA®

Launched in 1967, CORDURA is a premier brand of high-performance fabrics renowned for exceptional durability and high abrasion resistance.

Originally developed by DuPont, the CORDURA® brand became part of Invista following its spin-off in 2004. Under Invista’s ownership, CORDURA evolved into a leading high‑performance fabric brand. As of now, Invista continues to own the CORDURA brand which continues to be a benchmark for ruggedness in military, workwear, and outdoor gear, from jeans to jackets, backpacks to work boots.

Teflon™

A coating that withstands high temperatures and provides oil resistance, stain resistance, and reduced friction.

Teflon is a renowned brand of fluoropolymer coatings, best known for its exceptional non-stick and heat-resistant properties. The brand's ownership has evolved over time:

-

Origins at DuPont: Teflon was accidentally discovered by DuPont chemist Roy Plunkett in 1938 and subsequently introduced to the market by DuPont.

-

The Invista Era: In 2004, following the spin-off of DuPont's textiles division, the Teflon brand became part of the newly formed company, Invista.

-

Current Stewardship: In 2019, Invista's apparel and advanced textiles business—including the Teflon brand—was acquired and rebranded as The LYCRA Company.

Today, Teflon coatings are widely used in cookware, industrial applications, and textile treatments for workwear and heavy-duty outdoor gear, providing durable water, oil, and stain repellency.

Ripstop Nylon / Polyester

Ripstop fabrics are a big improvement for outdoor clothing. These fabrics have a special grid pattern with thicker threads. The thicker threads are woven into a thinner base material. This design stops small rips from getting bigger. This fabric is widely used for outdoor jackets, tents and backpacks.

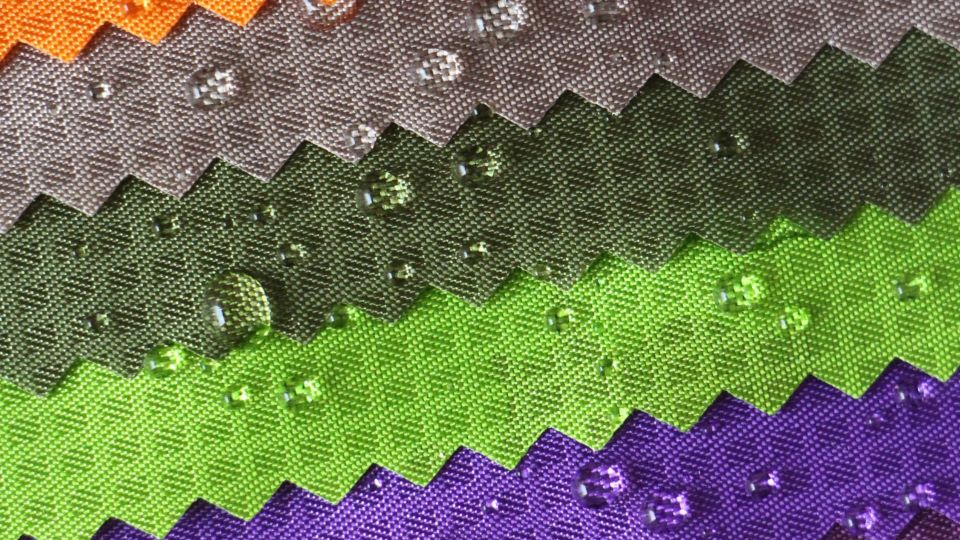

DWR (Durable Water Repellent)

DWR fabric, or Durable Water Repellent fabric, is a type of material treated with a coating to make it water-resistant. It has a thin coating that stops water from soaking in. Water forms drops and rolls off the surface instead.

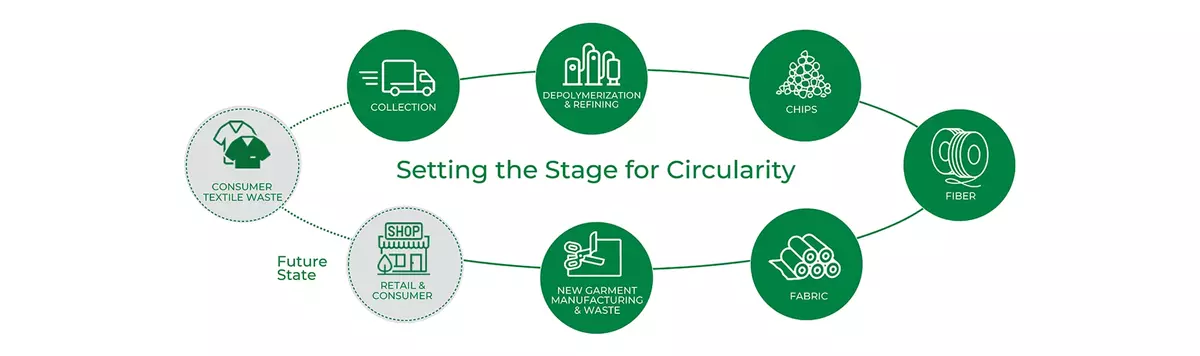

Sustainable Fibers & Eco Trends

ECONYL®

ECONYL® is a sustainable nylon material renowned for its innovative regeneration process and high performance.

-

Origins at Aquafil: ECONYL® was developed and is manufactured by the Italian company Aquafil. It was introduced as an innovative solution to transform waste materials into high-value nylon.

-

Regeneration Process: The ECONYL® system regenerates discarded materials such as fishing nets, fabric scraps, and industrial plastic into virgin-quality nylon through a proprietary purification and polymerization process.

-

Current Status: ECONYL® remains under the ownership and management of the Aquafil Group, which continues to drive its global expansion and application development.

The ECONYL® Regeneration System rescues waste that would otherwise pollute the Earth.

Fishing nets, fabric scraps, carpet flooring, and industrial plastic are collected from all corners of the world to be transformed. Once retrieved, the waste materials are carefully sorted and cleaned to recover all of the nylon possible.

Today, ECONYL® regenerated nylon is widely used in fashion, carpets, sportswear, and outdoor clothing, offering the same quality as conventional nylon while supporting circular economy principles and reducing environmental impact.

REPREVE® Our Ocean™

REPREVE® Our Ocean™ is a specialized recycled performance fiber made from bottles collected within 50 kilometers of coastlines in countries or areas that lack formal waste or recycling systems.

REPREVE® Our Ocean™ was developed and is produced by Unifi, Inc., a global textile solutions company, as part of its broader REPREVE® recycled portfolio.

The fiber directly transforms collected ocean-bound plastic bottles into traceable, certified recycled polyester with performance properties, providing brands with a measurable solution for reducing marine plastic waste.

Today, REPREVE® Our Ocean™ is used by leading apparel, footwear, and accessory brands to create sustainable products with verified environmental benefits, combining performance with proven plastic diversion from coastal areas.

Netplus®

Pertex Netplus® Fabric is made from 100% post-consumer recycled fishing net.

Bureo® is the maker of Netplus material and works directly with fishing communities to collect discarded fishing net waste, bringing positive, end-of-use solutions to the most harmful form of ocean pollution, reducing the need to extract fossil fuels and preventing a harmful waste from entering the environment.

From performance fabrics to hat brims and more, the possibilities with NetPlus material are endless.

S.Café®

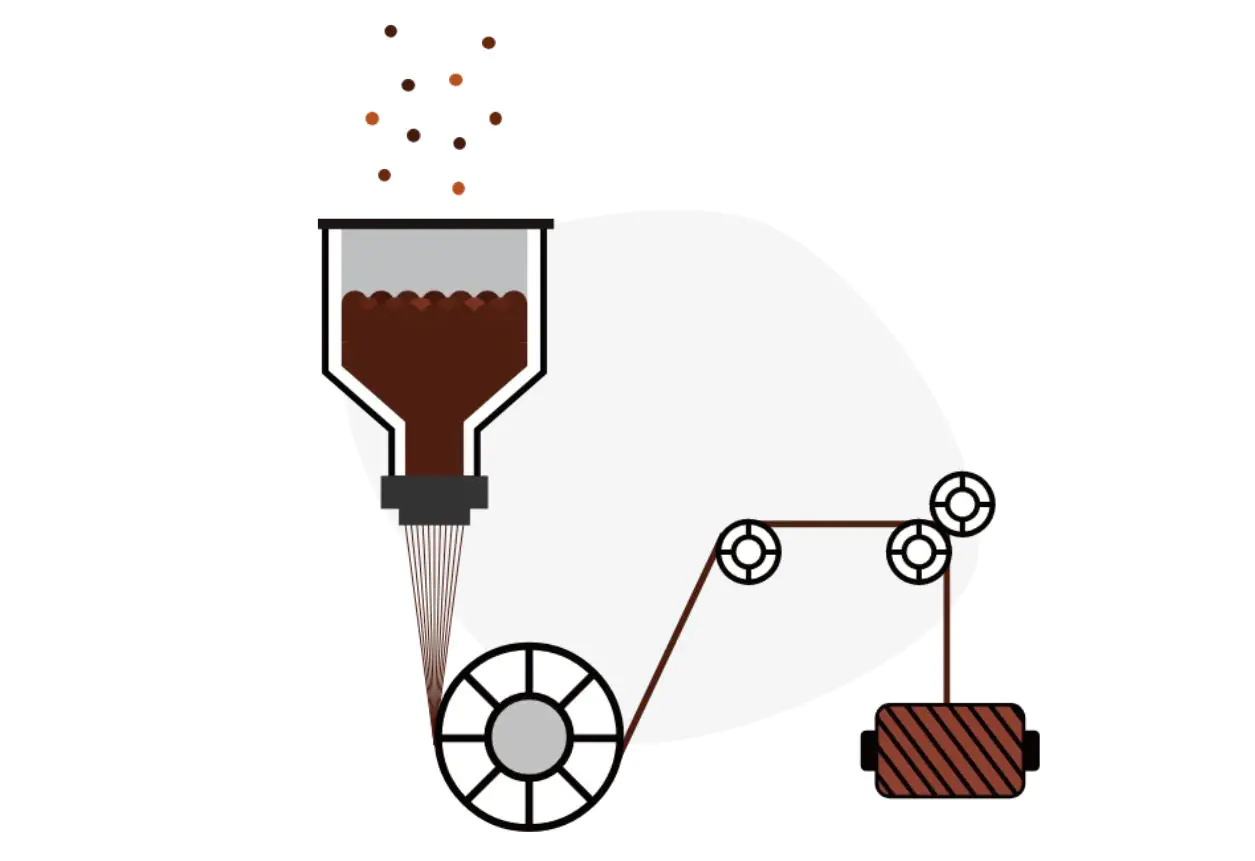

S.Café® is an innovative eco-friendly yarn technology that transforms used coffee grounds into functional textiles.

S.Café® was developed and introduced by Singtex Industrial Co., a textile manufacturer in Taiwan PRC, known for its sustainable material solutions.

The technology upcycles waste coffee grounds into yarn with natural odor control, UV protection, and fast-drying properties, creating value from waste while reducing dependence on virgin petroleum-based materials.

Today, S.Café® technology is used by leading outdoor, lifestyle, and fashion brands to create performance apparel with enhanced comfort and verified sustainability benefits, offering a distinctive approach to eco-friendly textile innovation.

Tencel™ Lyocell & Modal

TENCEL™ Lyocell & Modal are premium botanic fiber brands known for their environmentally responsible closed-loop production process.

TENCEL™ Lyocell and Modal fibers are a lower-environmental impact, high-comfort material manufactured by Lenzing. They are made from natural, raw material wood sourced from responsibly managed forests and produced with 50% less carbon emissions and water consumption than generic lyocell and modal fibers.

TENCEL™ Lyocell fibers are soft and smooth to touch. They have high tenacity among cellulosic fibers, support a natural dry feeling through moisture control and enable a subtle sheen in fabrics. In addition to these performance benefits, TENCEL™ Lyocell fibers have a lower environmental impact and are made using a closed loop production process which recovers 99.8% of solvent.

TENCEL™ Modal fibers help to retain the softness of fabrics even after repeated washing and support a natural dry feeling through effective moisture control. TENCEL™ Modal fibers are produced using resource-efficient technology with high recovery rates of chemicals.

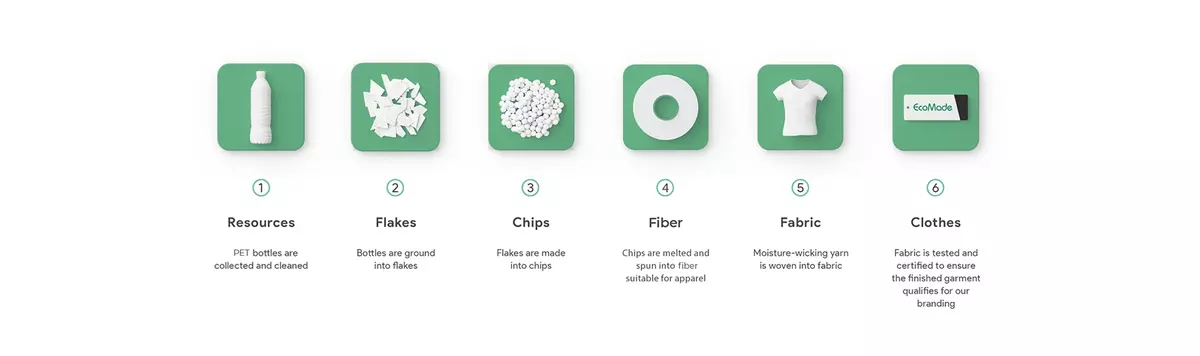

COOLMAX® EcoMade

COOLMAX® EcoMade fiber provides the same reliable cooling, moisture-wicking performance you expect from the COOLMAX® brand, but it’s made with 100% recycled resources.

COOLMAX® EcoMade fiber can be made with either 100% textile waste or 100% recycled PET bottles.

Conclusion

High-performance outdoor apparel is the result of a synergy between material engineering and human ergonomics. Understanding the technical origins and performance focus of each material helps designers build an effective “three-layer system” early in development.

While fabric performance is critical, material selection should follow a scenario-first, parameter-second approach:

- For high-altitude expeditions, prioritize waterproofness and durability.

- For hot-weather trail running, prioritize breathability and lightweight fabrics.

Targeted reinforcement in high-abrasion areas extends product lifespan and maximizes cost-effectiveness — allowing each piece of high-performance gear to truly accompany users further.

From the waterproof protection of a GORE-TEX shell to the moisture-wicking comfort of a Merino wool base layer, the world of outdoor apparel is a testament to material innovation.

This guide has detailed the core technologies—shell membranes like eVent and Dermizax, insulation like PrimaLoft and Climashield, and base layers like Polartec Power Dry—that form the reliable three-layer system.

As the industry evolves, a new chapter is being written with sustainable solutions like ECONYL® and PrimaLoft® Bio™.

The key takeaway is that there is no single 'best' fabric, only the right material for your specific activity and environment. By understanding these technologies, you can make informed choices, ensuring your gear is not only high-performing but also perfectly suited to accompany you on every adventure.