Laser1 cutting has emerged as a game-changing technology in the clothing manufacturing industry, offering unmatched precision, efficiency, and versatility. In this article, we’ll explore how laser cutting works, its benefits, applications, and the challenges it presents.

What is Laser Cutting?

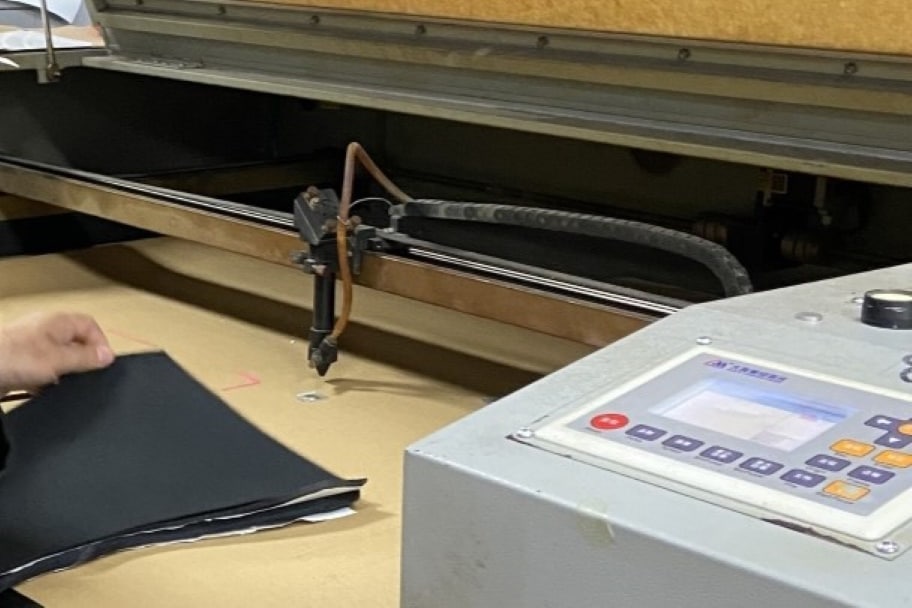

Laser cutting is a technology that uses a high-powered laser beam to cut materials with extreme precision.

In clothing manufacturing, it is primarily used to cut fabrics, but it can also engrave, perforate, and etch designs. The laser beam is controlled by computer software, ensuring accuracy and consistency in every cut. Unlike traditional cutting methods, laser cutting is a non-contact process, which means it minimizes fabric distortion and fraying.

How is Laser Cutting Used in Clothing Manufacturing?

| Application | How It Works | Benefits |

|---|---|---|

| Precision Cutting of Fabric | The laser beam follows a digital template to cut fabric into precise shapes. | Ensures clean edges, reduces waste, and allows for intricate designs. |

| Intricate Design and Detailing | The laser cuts complex patterns, lace-like designs, and perforations. | Adds unique aesthetic value without compromising fabric integrity. |

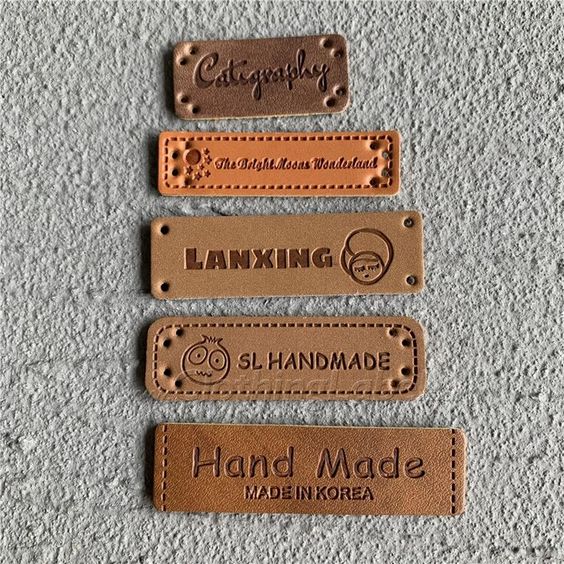

| Engraving and Etching | The laser lightly burns the fabric surface to create designs, logos, or textures. | Provides a permanent and precise way to customize garments. |

| Sealing Fabric Edges | The laser melts the edges of synthetic fabrics, preventing fraying. | Eliminates the need for hemming or overlocking, saving time and labor. |

| Prototyping and Small-Batch Production | Laser cutting allows for quick and accurate prototyping of new designs. | Reduces development time and costs, enabling faster market entry. |

Benefits of Laser Cutting in Clothing Manufacturing

| Benefit | Description |

|---|---|

| Precision and Accuracy | Ensures clean, precise cuts, even for the most intricate designs. |

| Versatility | Can cut a wide range of fabrics, including polyester, cotton, leather, and more. |

| Efficiency | Faster than manual cutting methods, especially for intricate patterns. |

| Reduced Waste | Optimizes fabric usage by nesting patterns closely together. |

| Enhanced Quality | Produces clean, sealed edges that prevent fraying. |

Applications of Laser Cutting in Clothing Manufacturing

| Apparel Type | Applications | |

|---|---|---|

| Technical and Outdoor Clothing | Waterproof seams and reinforced panels for high-performance gear. | |

| Sportswear and Activewear | Precision panels, ventilation perforations, and sealed edges for durability. | |

| Denim and Casual Wear | Distressed effects and precise pocket/hem detailing. | |

| Lingerie | Handling delicate fabrics and adding decorative patterns. |

Conclusion

Laser cutting has become an indispensable tool in clothing manufacturing, offering unmatched precision, efficiency, and versatility. From outdoor clothing to sportswear, this technology enables manufacturers to streamline their processes, create high-quality, intricate, and customized garments with minimal waste. As the clothing industry continues to evolve, laser cutting will play an increasingly important role in meeting the demands for innovation, performance, and quality.

-

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. ↩