Reflective printing uses special materials to make things brighter. It reflects light back to where it came from. This helps objects stand out in the dark. It is useful for safety, like bright high-visibility clothes for workers. It is also used in design to make items look cool. You can see it on road signs or trendy clothes. This technology is both useful and creative for many needs.

Key Takeaways

Reflective printing uses special materials to bounce back light. This helps objects be seen in the dark and keeps people safe.

Materials like glass beads and prisms reflect light without power. They use natural light, making them save energy.

Reflective heat transfer vinyl (HTV) is often used on clothes. It adds shiny designs and is great for sportswear and fashion.

Reflective signs make roads safer by staying bright at night. Research shows they lower accidents and save lives.

The demand for reflective materials is growing fast in many industries. This shows how important visibility is in daily life.

What Is Reflective Printing?

Definition and Key Features

Reflective printing uses special materials to make things visible in dim light. These materials, called reflective materials, send light back to where it came from. This makes reflective printing important for safety and creative uses. You can find it on road signs, safety gear, or cool clothing.

A big advantage of reflective printing is that it doesn’t need electricity. Unlike lights or LEDs, it works with outside light, like car headlights. This makes it energy-saving and useful for many things. Another benefit is its toughness. Reflective materials can handle bad weather, so they work well outdoors.

How Reflective Printing Works

Reflective printing changes how light behaves. When light hits a reflective surface, it doesn’t spread everywhere. Instead, it goes straight back to the light source. This happens because of certain light rules used in reflective materials.

Here’s a simple list of the rules behind reflective printing:

Principle | What It Means |

|---|---|

Specular Reflection | Light bounces off a shiny surface like a mirror. |

Refraction | Light bends when it moves through different materials. |

Total Internal Reflection | Light stays inside a clear surface at certain angles instead of escaping. |

Reflective materials mix these rules to shine brightly. Tiny glass beads or special spheres are often used. These small parts bend and send light back, making things glow. Another method uses tiny prisms to direct light in the same way.

When you see reflective printing, like on a road sign, these light tricks are working. The reflective material keeps the sign bright even in the dark, helping drivers stay safe.

Materials and Techniques in Reflective Printing

Glass Beads and Retroreflective Microspheres

Glass beads and retroreflective microspheres are tiny parts that reflect light. These beads are round and clear, letting light enter and bounce back. You can find this technology on road signs and safety clothing.

Retroreflective microspheres bend light inside the bead. This bending sends the light back to where it came from. The size and quality of the beads affect how well they work. Bigger beads reflect more light but are less flexible. Smaller beads are more flexible but reflect less light.

Prism Technology

Prism technology uses small prisms to reflect light back. These prisms are shaped to send light to its source, like glass beads. But prisms are brighter and more precise. You’ll see this in top-quality reflective signs and special safety gear.

Prisms are strong and last in tough weather. They resist water and heat, making them great for outdoor use. Manufacturers often mix prism technology with other reflective materials to improve visibility.

Reflective Heat Transfer Vinyl (Reflective HTV)

Reflective heat transfer vinyl, or reflective HTV, is used for reflective designs on clothes. Heat and pressure stick the reflective layer to fabric. You can use reflective HTV for bright clothing, sportswear, or creative fashion.

Reflective HTV comes in different types, like reflective heat transfer film. These options help you pick the right one for your project. High-quality reflective HTV is bright and lasts a long time.

This material is simple to use and works with most fabrics. It’s also light, so it’s comfortable to wear. Reflective HTV mixes style and safety, helping you stay visible and look good.

Types of Reflective Printing Methods

Reflective Heat Transfer Printing

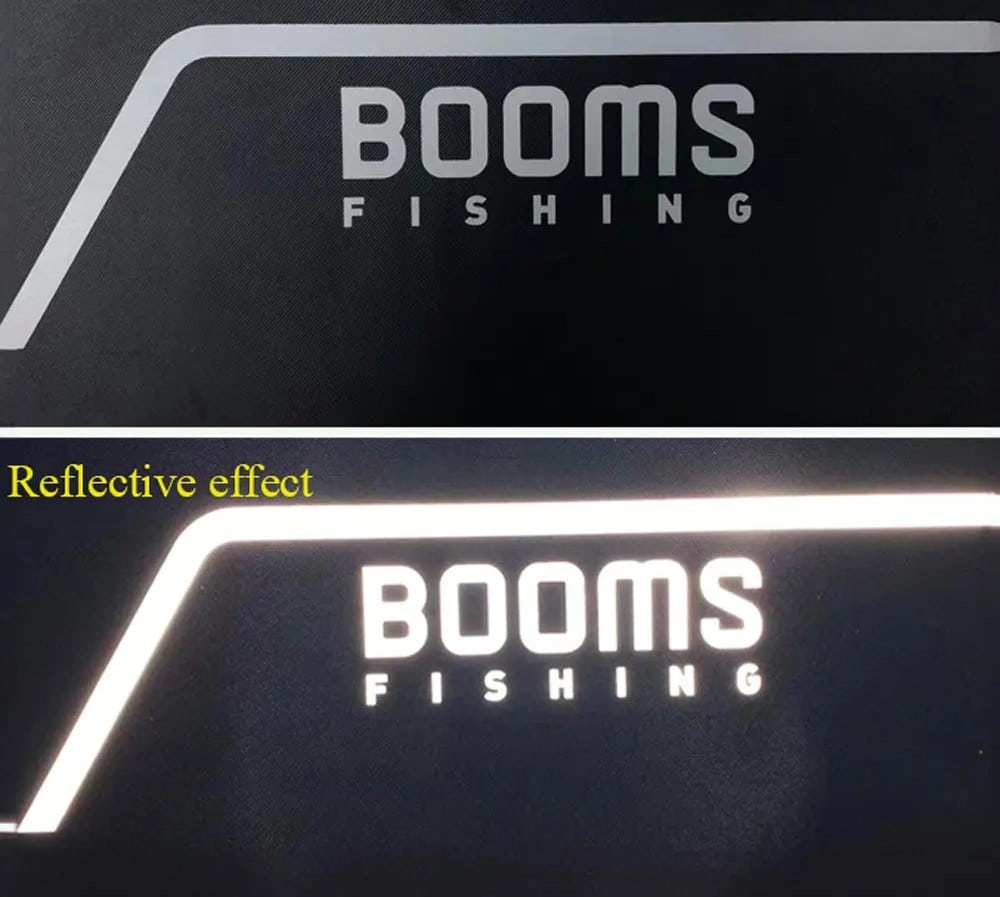

Reflective heat transfer printing adds shiny designs to clothes. It uses reflective heat transfer vinyl (HTV) for this purpose. Heat and pressure stick the reflective layer onto fabric. This method is easy and works well for beginners and experts.

Reflective HTV is flexible and fits most fabrics. It’s light, strong, and can be cut into shapes. Use it for bright clothing, sports gear, or creative outfits. For bigger projects, reflective heat transfer film is a good choice. Both options give bright and lasting results.

To start, you need a heat press or iron. Place the HTV on fabric, heat it, and peel off the backing. The reflective layer stays firmly in place, looking neat and professional. This method mixes safety with style, helping you shine in dim light.

Reflective Signs and Signage Printing

Reflective signs are important for safety and sharing information. These signs use special materials to stay bright at night. You see them on roads, near construction, or in parking areas. The shiny surface helps people read them in the dark.

Making reflective signs involves printing on reflective sheets. These sheets are placed on metal or plastic bases. Glass beads or prisms make the signs extra bright and tough. This process ensures the signs last through bad weather.

Reflective signs aren’t just for roads. They can be used for ads, events, or even home décor. This printing method is useful for both safety and creative projects.

Direct-to-Garment Reflective Printing

Direct-to-garment reflective printing puts shiny designs straight on fabric. Unlike HTV, it uses special printers and reflective ink. The ink sticks to the fabric, creating a smooth and strong finish.

This method is great for detailed designs like logos or patterns. It makes clothes more visible, perfect for safety gear or fashion. It’s also faster for making many items at once.

For the best results, use good reflective ink and the right printer. This works well on cotton, polyester, or mixed fabrics. It’s a simple way to add both function and style to clothing.

Practical Uses of Reflective Printing

Safety Gear and Bright Clothing

Reflective printing helps make safety gear and bright clothing. These clothes are important for workers in jobs like construction or roadwork. They help workers stay visible in dark or dangerous places. Reflective materials, like heat transfer vinyl (HTV), are added to clothes to make them shine in dim light. This keeps workers safe while they do their jobs.

Athletes also use reflective printing in sports clothes. Runners and cyclists wear these clothes to stay visible during early or late workouts. HTV lets you add cool designs to sportswear while staying safe. Whether you’re working or exercising, reflective clothes keep you safe and stylish.

Reflective Signs for Roads and Traffic

Reflective signs are very important for road safety. These signs use materials like glass beads or prisms to stay bright at night or in bad weather. Drivers depend on these signs to drive safely, making them a key part of road systems.

Temporary reflective signs are also useful. They guide traffic in construction zones or during events. Reflective printing makes signs tough and weatherproof. Whether it’s a stop sign or a detour marker, reflective signs stay clear and reliable.

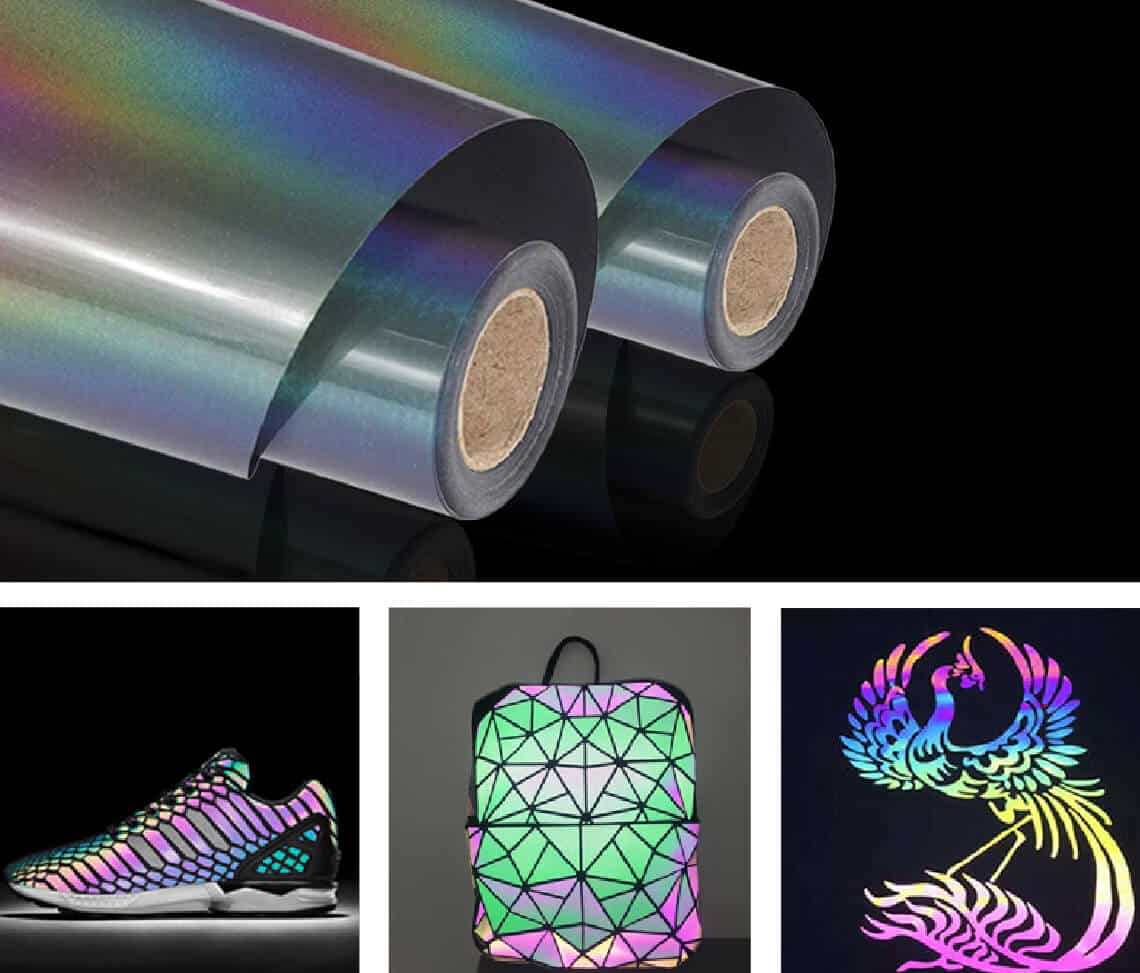

Fashion and Creative Designs

Reflective printing is popular in fashion and design. Designers use reflective materials to make clothes that are safe and stylish. Reflective heat transfer vinyl is great for adding fun designs to outfits. It mixes safety with creativity, perfect for trendy people.

Reflective fashion is growing fast. Sports brands use reflective threads to make workout clothes safer in dim light. Jackets and raincoats now have reflective parts for safety and style. These clothes are loved by commuters and outdoor fans.

Application | Description |

|---|---|

Sportswear | Reflective threads make workouts safer in low light. |

Fashion Industry | Everyday clothes use reflective materials for safety and style. |

Raincoats | Reflective parts add safety and style for outdoor lovers. |

Reflective printing lets you customize your clothes. You can create designs that show your personality and keep you visible. Whether it’s a bold outfit or a small detail, reflective printing makes your wardrobe unique.

Reflective printing uses special materials to improve safety and visibility. You’ve seen how glass beads, prisms, and reflective vinyl make shiny, strong surfaces. These tools are important for safety gear, road signs, and even stylish clothes.

Its use is growing fast. In 2023, the reflective materials market was worth $14.2 billion. It is expected to grow by 6.4% each year until 2030. More safety needs in jobs like construction and car-making drive this growth. Governments and groups focus on reflective products to prevent accidents. With 1.35 million road deaths each year, better safety is needed.

New ideas also aim to save energy and be eco-friendly. For instance, reflective paints lower electricity use in hot places. As these ideas grow, reflective printing will become more useful. It will mix safety with creative designs for many purposes.

FAQ

What makes reflective heat transfer vinyl different from regular vinyl?

Reflective HTV shines when light hits it, helping with visibility. Regular vinyl does not reflect light. Reflective HTV is applied with heat and pressure, while regular vinyl often uses glue. Reflective HTV adds both safety and style to clothes and items.

Can reflective heat transfer vinyl work on all fabrics?

Reflective HTV works on many fabrics like cotton, polyester, and blends. But it should not be used on heat-sensitive fabrics like nylon. Always check if the fabric can handle heat before using HTV to avoid damage.

How do you use reflective heat transfer vinyl?

To use reflective HTV, place it on the fabric. Use a heat press or iron to apply heat. Then, peel off the backing. The heat makes the vinyl stick to the fabric, giving a strong and neat finish.

Is reflective heat transfer vinyl long-lasting?

Yes, reflective HTV lasts a long time. It can handle washing, weather, and daily use. Using the right heat and pressure during application helps it stay in place. Follow care tips to keep its reflective shine.

Can reflective heat transfer vinyl be used for fun projects?

Yes! Reflective HTV is great for creative ideas. You can cut it into shapes, letters, or designs for clothes, bags, or other items. It mixes safety with creativity, making your projects unique and eye-catching.